YIZUMI Germany moves to a larger facility

Established in 2018 and located on the campus of the RWTH Aachen University, YIZUMI Germany GmbH will move to its new bigger home in Alsdorf near Aachen in June 2020.

This expansion is based on the strong growth of our innovative technologies which include extrusion-based additive manufacturing “SpaceA” or Thixomolding for the manufacturing of magnesium lightweight components. The new, more suitable location will also support our Die Casting business unit to provide fully automated casting solutions for the manufacturing of aluminium as well as magnesium components.

YIZUMI Germany additionally develops special processes around foam injection moulding (Foam Pro) and the innovative combination technology “Polyurethan plus Injection Moulding” (React Pro). The YIZUMI technology portfolio is complemented by Rubber injection moulding equipment and processes.

Besides offices for our researchers, sales and admin, the new location will provide appropriate space for a tech-center as well as assembly activities.

Performance improvements on Gen-II Die Casting machine

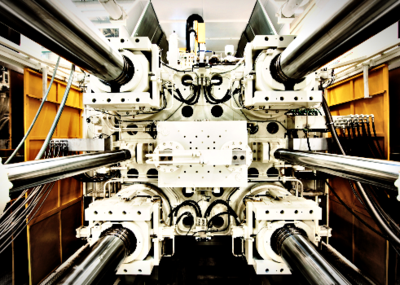

To further support our customers to stay competitive in the die casting market, YIZUMI will be introducing an improved 2nd generation (Gen-II) of its successful H series die casting machines (180 – 900t)

Our R&D team, in collaboration with our European experts, has introduced innovations with a clear focus on improved injection capability and performance. The result is an upgrade package providing significantly increased shot control precision and high injection repeatability.

These technological improvements strongly facilitate our customer`s high performance manufacturing capability allowing them to successfully compete.

With its optimized hydraulic system, the Gen-II system offers a high injection acceleration of ≥50G. In combination with its high capacity P/Q performance, the Gen-II die casting machine is built to provide high casting quality of even the most difficult of parts.

Further improved intensification pressure build-up time, in combination with a highly increased precision in the switch-over to the fast cavity-filling-phase (+/-2mm), greatly increases precision and repeatability for the casting of critical, high requirement components.

The YIZUM DM Gen-II machine range also offers additional transparency and support for die casting process engineers in the field of PQ2 display with the actual operating point as well as an elaborate tool to calculate technology- related data and process parameters.

The upcoming expo China DieCasting in Shanghai (July 15-17, 2020) offers a great opportunity to take a personal look at our innovations. Visit YIZUMI in Hall N2-A22/23

Efficient magnesium processing with Thixomolding

After the successful development of the MGII thixomolding machine series with a clamping force of 6,500 kN in 2015, Yizumi has made another breakthrough in the production of large thixomolded magnesium alloy components.

Together, the engineers from Yizumi China and Yizumi Germany have developed a thixomolding machine with a clamping force of 12,500 kN, making it one of the world's largest thixomolding machines to-date.

The machine was commissioned in 2019 at Castwerk in Frankenberg (Germany) and is currently in operation. Castwerk is involved in the production of large magnesium alloy components for the automobile and urban mobility sectors.

“It is our plan to utilize our new 1,250 t YIZUMI Thixomoulding machine for the manufacturing of footboards for E-scooters, components for E-bikes or the moulding of large automotive cockpit carriers” says Castwerk Managing Director Michael Schran.

Having mastered the two core technologies of high-speed injection control in combination with our robust magnesium processing injection unit, YIZUMI is now able to offer lightweight manufacturing solutions to the fast-growing markets of electro- & urban mobility and automotive interiors. Thixomoulding offers great advantages in the processing of magnesium for a wide range of applications.