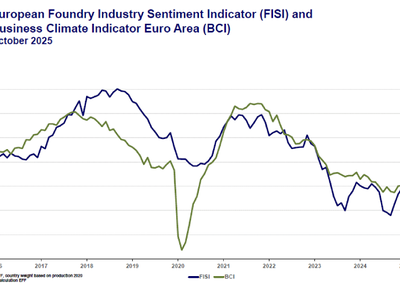

Prof. Dr.-Ing. Wolfram Volk and Dr.-Ing. Steffen Klan opened the 2025 Barbara Conference of the VDG Bavarian Regional Group at Fraunhofer IGCV in Garching with warm words. Right at the start, Volk reminded the audience that the foundry industry had seen easier times. Increasing international competition, changing conditions and global upheavals were putting pressure on the industry. This made it all the more important, he emphasised, to actively shape global networking, strengthen cooperation and jointly develop strategies for the future. Only in this way could the position of Germany and Europe as foundry locations be secured in the long term.

This message fitted in seamlessly with the conference motto: ‘The fascination of casting’. Volk reported that castings repeatedly amazed students, especially those with no previous experience in manufacturing. For him, these reactions were a clear indication of the high technical level of the industry. At the same time, he called for greater public focus on the strengths of foundry technology. For him, these include above all:

- high innovative strength,

- great design freedom,

- broad industrial relevance,

- continuous progress in quality assurance and process robustness.

A day of expertise, research and networking

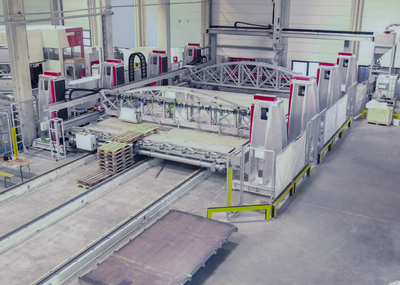

As is tradition, the Barbara Conference attracted around 160 participants to Garching this year. In addition to three specialist presentations, the research marketplace in the experimental foundry offered a comprehensive insight into current developments.

In addition to Fraunhofer IGCV, TUM utg, the universities of Aalen and Kempten, and several start-ups were also represented. The event concluded with a joint dinner – a strong forum for collegial exchange and interdisciplinary networking.

Impulses from industry: three presentations, three perspectives

The presentation programme covered a broad spectrum of modern foundry technology:

- Lightweight construction with high functional integration

Dr Timo Hanss and Tobias Arnold, BMW AG

- Transformation and change at the Augsburg iron foundry

Marco Nagler, Everllence SE

- Extraordinary casting – From boxer engines and fittings: Technology meets emotion and design

Joshua Bissels, Pinter Guss GmbH