J.D. Neuhaus GmbH & Co. KG in Witten, Germany, will celebrate its 270-year anniversary. Founded in 1745, the oldest machine construction company in Germany is today in its seventh generation of uninterrupted family ownership. What began as a winch forge for wooden-shaft winches has developed over the years into the world market leader for pneumatic and hydraulic hoists and crane systems.

J.D. Neuhaus GmbH & Co. KG in Witten, Germany, will celebrate its 270-year anniversary. Founded in 1745, the oldest machine construction company in Germany is today in its seventh generation of uninterrupted family ownership. What began as a winch forge for wooden-shaft winches has developed over the years into the world market leader for pneumatic and hydraulic hoists and crane systems.

The development from a manufacturer of wooden-shaft winches, which were indispensable as „lifting gear“ to eighteenth century waggoners due to the road conditions of the time, into a modern industrial company has been a long one. It all began more than 270 years ago with entry of a winch forge run by Johann Diederich Conrad Neuhaus in the “Sprockhövel Register of Manufacturers”. The descendants of the founder continued to produce winches. These were produced by hand until well into the 20th century and were mainly supplied to mining companies, small businesses, waggoners and agricultural enterprises. The foundations for the innovative, growth-oriented business enterprise were laid in 1952. At the time, JDN replaced the hand drive commonly used in hoists with an air motor. This innovation revolutionised the range of applications, initially in the mining sector, and also marked the economic upturn for the company.

Having developed alongside the mining industry, JDN also had to weather the economic crises associated with mining. The company succeeded in making structural changes by expanding into new business areas for air hoists and by developing its export business.

In 1966, when J.D. Neuhaus still carried the addendum „winch factory“ and communication was predominantly via telex machine, the first JDN Air Hoists for applications outside underground mining with capacities of 250 to 1000 kg were launched onto the market. In the search for further areas of application, the chemical industry was found to offer potential because, just as in underground mining, explosion hazards existed in many areas. And, thanks to their drive medium, JDN Air Hoists are predestined for precisely these applications. Moreover, they offer further advantages, as could be read in a JDN brochure dating from 1966: „Light in weight, low in headroom, fast in lifting speed, quiet in acoustics, low in air consumption and infinitely variable in control“.

During the following years, J.D. Neuhaus regularly introduced air hoists with higher capacities onto the market. In 1979, the highlight was the Profi 100 TI, the first air hoist worldwide with a capacity of 100 tonnes. In the same year, JDN also introduced the monorail hoists. These were specially developed for BOP handling in the offshore industry.

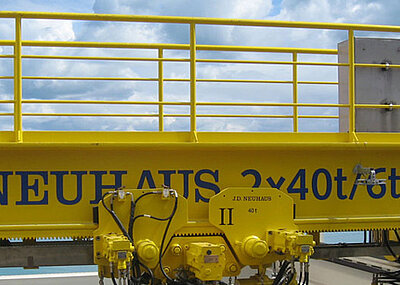

From 2003 to 2005, a complete relaunch of the JDN product line up to 20 t capacity was implemented. In 2010, there followed hoists with capacities of 25 to 50 t and finally in 2014, those with capacities of up to 100 tonnes. In this way, the entire series was optimised and set a new standard in the field of pneumatic hoists. Parallel to these developments, the plant construction business unit was founded in 2011. Here, JDN specialised on the development and construction of customer-specific crane systems, which are used mainly on offshore drilling rigs.

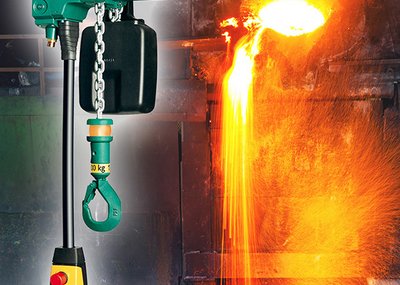

As an alternative to compressed air, J.D. Neuhaus also offers its entire product line with hydraulic drives. The areas of application extend from the automotive through to the cement industry. Here, the main focus is on the oil and gas exploration and processing sectors, mining, the chemical industry and heavy plant construction. And in accordance with the JDN claim „engineered for extremes“, applications in Siberia at minus 45° Celsius as well as 70 metres below the surface of the sea are not unusual.

Wilfried Neuhaus-Galladé has been the head of the company since 1995. Under his management, the course of the family-owned business has been adapted to the changed conditions predominant in global markets. He founded sales companies in the USA, France, Singapore and the UK, which provide a close-meshed, worldwide network in cooperation with international partners. The share of exportsis over 80%.

Quality, environmental protection, employee orientation and highly effective processes play a key role in the production and operation of Neuhaus products. The company’s environment management system was certified by the TÜV Rheinland Technical Control Association in 2009. JDN has been reviewing its quality management system on a regular basis since 1991.

Methods such as Kaizen, CIP, Kanban, Lean Production and ERP serve as basis for the whole JDN Group, which achieved a Group turnover of around 50 million euros in 2014. Annual production amounts to 6,000 to 8,000 hoists.

At present, J.D. Neuhaus employs a workforce of 215, of which 160 work at the production site in Witten, Germany. „The course has been set for dynamic and future-oriented development. The skills, motivation and commitment of our employees are first class and there is a wealth of potential for ideas and entrepreneurial imagination. We are ready for the future,“ says Wilfried Neuhaus-Galladé.