SCHAUMBURG, Ill. (USA) - The metalcasting industry recognized nine cast components as top designs for the 2008 Engineered Casting Solutions and American Foundry Society Casting Competition. The components are being used in a variety of industries, including material handling, agriculture, energy production, military, heavy truck and automotive.

AFS awarded one overall honor, plus four Best-in-Class honors and four Honorable Mentions.

<link file:7067> |

Carley Foundry Inc., Blaine, Minn., earned top honors in the annual competition for its Harley-Davidson oil tank. The component houses and circulates oil throughout the new Harley Rocker's operating system and is an important cosmetic item.

Carley's component was cast in A356-T6 aluminum via semi-permanent molding; it weighs 9.25 lbs. and measures 14 x 10 x 8 in. The casting offered improved cosmetics and better heat resistance than a proposed plastic design and also beat out a multi-piece fabrication.

2008 Best In Class

Material Handling Steering/Linkage Assembly, Piad Precision Casting Corp., Greensburg, Pa. This brass permanent mold chill casting was redesigned from a weldment composed of 10 pre-fabricated pieces, 19 weld joints and four bushings. The 9.82-lb. steering linkage was 10% lighter than the weldment and eliminated some machining and the need for stress relieving.

Agri-Speed Hitch, Dotson Iron Castings, Mankato, Minn. This assembly of austempered ductile iron and ductile iron green sand castings was reverse engineered from the customer's weldment, resulting in a 30% weight reduction and 40% cost reduction. The agricultural hitch enables the automatic hookup and disconnection of farm equipment.

Static Mixer Tube, Castalloy Corp., Waukesha, Wis. A highly abrasion resistant, 124-lb. white iron nobake sand casting, the part is ideal for use in the cleansing of ground coal in power generation facilities. The casting was converted from a seven-piece fabrication, eliminating all assembly labor and allowing for the strategic thickening of wear areas, which extends the service life of the component.

Military Main Transmission Housing, Denison Industries, Denison, Texas. Denison converted a multi-piece assembly into this 200-lb., A356-T71 aluminum nobake sand casting. The conversion eliminated tubing, hydraulic lines and passageways by casting them into the design, which required 77 cores.

2008 Honorable Mention

Volvo Multifunction Bracket/Towing Eye, Citation Columbiana, Columbiana, Ala. A 21-lb. ductile iron lost foam casting, the part eliminated the machining and heat treating required on previous brackets. It realized a 1.5-lb. weight reduction and 35.4% cost savings with cast-in frame mounting and cross-member mounting surfaces, a tow pin receiver, holes for radiator brackets and bumper bracket attachments.

Horsepower Freaks Intake Manifold, Trilore Technologies Inc., Alamo, Calif. The metalcaster employed a proprietary rubber-plaster mold process to produce this 13 lb., highly polished A356-T6 aluminum conversion from plastic. The manufacturing method, known as the ME process, is capable of producing thin-walled castings with tight grain structure.

Cadillac CTS Engine Cradle, General Motors Corp. and Diversified Machine Inc., Warren, Mich. The 33.5-lb. vacuum riserless/pressure riserless casting was poured in A356 aluminum and welded to four aluminum extrusions to form the engine cradle for a Cadillac. It reduced mass by 40% and consolidated 32 parts to one from a previous steel design.

Rear Motorcycle Frame, Eck Industries, Manitowoc, Wis. Eck Industries utilized the ablation process to make this 4.9-lb. A356-T6 aluminum part with enhanced mechanical properties in its thin sections. The component, which fits on the tail section of a Buell Motorcycle Co. bike, saved weight and cost by incorporating the motorcycle's shock mount location.

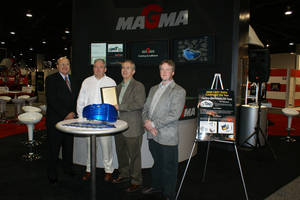

This year's Casting Competition was sponsored by MAGMA Foundry Technologies, Schaumburg, Ill. MAGMA will provide Carley Foundry Inc. with a one-year license of MAGMASOFT software, including training and implementation assistance.