Andy Street received a socially distanced tour of the aluminium casting specialist’s facility in Wednesbury to understand how the company is bouncing back from Covid-19 by targeting new opportunities in lightweighting - a major growth market with castings at its heart.

He talked to staff at the business to understand how it is supporting major OEMs in the automotive sector, as well as supplying parts to the hydraulics and chemical sectors.

There was also time to find out more about the £2.2m investment in a new CNC machining shop that features six 5-axis CNC machines, providing bed sizes ranging from 400mm to 630mm.

This latest equipment will give Alucast the speed and precision necessary to meet just-in-time delivery requirements of existing and future orders.

Andy Street commented: “It was great to be in the Black Country, where manufacturing is in our blood. Despite the pandemic and all the challenges it has thrown at industry, companies like Alucast are innovating and adapting, investing in their strengths to achieve new sales opportunities and make the most of the green revolution.”

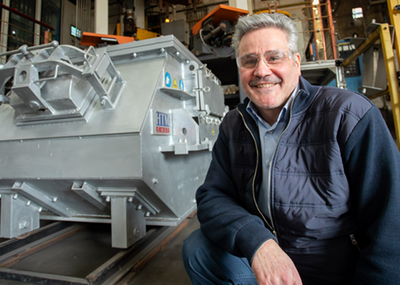

Tony Sartorius, Chairman of Alucast, concluded: “It was great to show Andy what we have been doing and the manufacturing strengths that still exist in the Black Country. We are a region with fantastic technical skills, a passion to do new things and a desire to play our own significant role in the next transport evolution.

“Our sand, gravity and low/high pressure castings are ideally suited for the automotive sector’s move towards lighter parts and we have already won over £3m of new work in this arena over recent years.”