Three years ago, Wheelabrator made a deliberate decision to step back in order to move forward.

With more than a century of industrial heritage, the company has long combined deep technical expertise with a vast installed base. Over time, however, this legacy also introduced complexity: an extremely broad product portfolio, regional variations, and critical knowledge concentrated in individuals. While customers continued to trust the technology, doing business had gradually become more complicated than necessary. Recognizing this was the starting point of a focused and disciplined transformation.

The transformation was initiated under the leadership of Lars Priess, who stepped in at a decisive moment to set a clear strategic direction. Nearly two years ago, Magda Höltke joined the Wheelabrator leadership team, further strengthening the journey with additional strategic and operational focus. Together, they played a central role in translating intent into execution. Their leadership accelerated portfolio clarity, organizational alignment, and a stronger customer-centric mindset, anchoring the shift from legacy-driven complexity toward structured, scalable performance across the business.

Rather than optimizing isolated functions, Wheelabrator began addressing the entire value chain, from first customer interaction through engineering, manufacturing, delivery, and aftermarket support. The objective was clear and consistent: create tangible customer value through clarity, speed, and predictability.

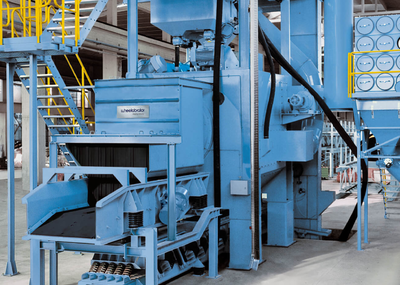

From Portfolio Breadth to Strategic Clarity. One of the earliest and most decisive steps was portfolio alignment. The blast turbine portfolio has been aligned into three clearly defined product families and the machine portfolio is now being restructured into eight clearly defined machine families comprising 34 machine types. This was not a reduction of capability, but a reframing of it. Clear application logic and value propositions now guide customers more easily, while internally enabling faster quotation processes, more efficient engineering, streamlined production, and stronger digital integration.

Crucially, this standardization did not come at the expense of customization. By standardizing platforms, architectures, and engineering logic, Wheelabrator created a robust and scalable foundation, while preserving full flexibility at the application level. Process parameters, wear protection concepts, automation, blast media strategies, and digital integration can still be tailored to specific customer requirements. The result is a balance of reliability and individuality: standardized where it adds efficiency, customized where it drives performance.

A defining cultural shift can be captured in four words: Art out. Science in. Where solutions were once driven largely by individual expertise and trial-and-error, Wheelabrator now operates in a far more data-driven, structured, and science-based way. Systematic testing, material analysis, and digital insights increasingly replace intuition, reducing uncertainty and embedding learning across the organization.

This shift is tangible in Wheelabrator’s state-of-the-art test center and laboratory facilities. Customers can validate processes, materials, and configurations under real operating conditions before making investment decisions. Advanced material science transforms wear from a passive acceptance into an actively managed variable, helping optimize lifetime performance. Testing has evolved from a supporting activity into a core element of solution development.

The transformation is not about abandoning history, but about leveraging historical strengths in a more modern and scalable way. Deep application knowledge and engineering expertise remain central, while clearer global structures, strengthened teams, and active succession planning enable a more agile and collaborative organization. Today, Wheelabrator operates with a stronger focus on repeatable solutions rather than one-off fixes.

R&D has shifted from project-specific experimentation toward solving customer challenges that apply across industries, with a clear emphasis on measurable Total Cost of Ownership drivers such as shot media consumption, component lifetime, and energy efficiency.

Digitalization further accelerates this shift. With Monitizer, Norican’s IIoT platform embedded in Wheelabrator machines, customers gain real-time process transparency and data-based decision support. By addressing key cost drivers such as energy consumption, wear, uptime, and maintenance, Monitizer supports predictable operations and long-term process optimization.

Measurable Impact. Improved project discipline, clearer specifications, and stronger portfolio focus have reduced margin leakage and improved delivery reliability. After earlier challenges, the machine business returned to positive performance driven by execution quality rather than price increases. For customers, this translates into clearer communication, higher predictability, and lifecycle-oriented solutions.

A Different Wheelabrator Today. Customers returning after several years would still recognize the heritage, but they would experience a different company: more modern, easier to do business with, more transparent, more data-driven, and better equipped to support successful production environments.

Three years into its journey, Wheelabrator has turned complexity into clarity and legacy into leverage. The direction is set: end-to-end effectiveness, scientific rigor, and long-term partnership. Anyone can blast a surface. Wheelabrator goes further.