Heidenreich & Harbeck have been manufacturing complex castings in Mölln since 1927. The company develops, casts and machines high-quality components in small and large batch sizes under the slogan “Quality from a single cast”. At Heidenreich & Harbeck, customers can obtain ready-to-install casting components weighing up to 16 tonnes from a single source.

Starting point / Task definition:

Heidenreich & Harbeck – a company steeped in tradition – turned to Boll Automation to develop an automation solution which enables a fully automated, robot-based finishing process despite the undefined formation of casting burrs

Implementation / Solution:

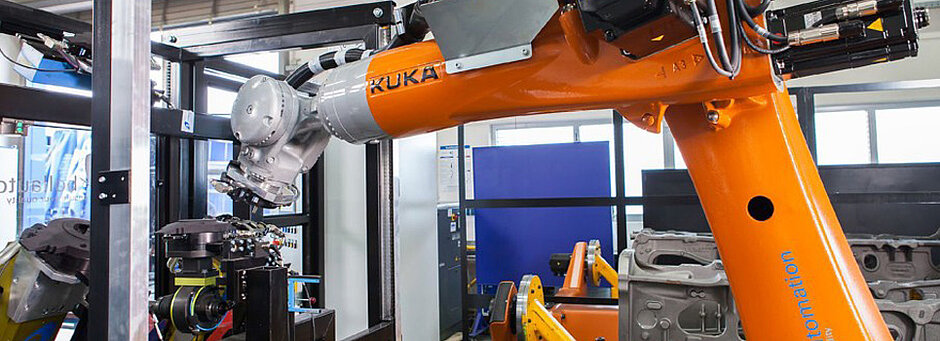

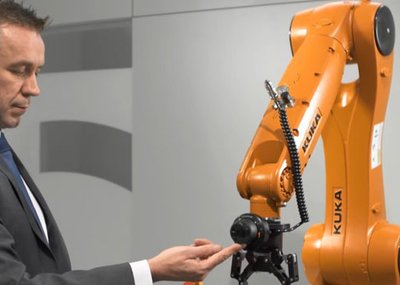

Previously at Heidenreich & Harbeck, the undefined formation of casting burrs made robot-supported automation for finishing difficult and, in some cases, even impossible. With the new solution, the company has now been able to successfully meet this challenge. The shelf-mounted KUKA Foundry robot at Heidenreich & Harbeck is equipped with multiple machining aggregate components for cleaning and grinding the casting burrs. Once the burr is assessed exactly, the robot commences the precise finishing with high reproducibility. The robot specialists at Boll Automation were able to overcome the undefined nature of the castings using upstream inspection technology and thus enable selective finishing.

System components:

The robot used – the KUKA KR 120 R2900 F extra – was not only equipped with a tool changing system for picking up machining tools, but also with an additional sensor system that detects exact position of the various burr contours.

The six-axis robot is from the KUKA KR QUANTEC series for operation as a Foundry variant. KUKA KR QUANTEC robots are particularly compact and enable space-saving cell concepts. Beyond this, the 29 basic robot types of the series stand out for their range of payloads (from 90 to 300 kg), their reaches (from 2,500 to 3,900 mm) and their long intervals between maintenance (up to 20,000 hours of operation).

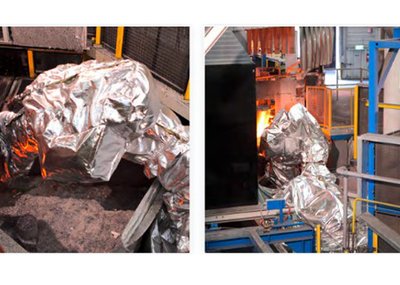

All models are installed on a compact base frame, with a nearly identical hole pattern for fastening to the mounting base. The foundry design also has a few additional advantages that were developed specifically for foundries: thanks to the use of special coatings, a heat-, corrosion-, alkali- and acid-resistant surface protects the robot. Additional protection is provided by special seals at the motor and gear unit flanges. The foundry wrists hold gripper tooling made of special heat-resistant steel and are provided with a special aluminum white painting for even more heat resistance in this particularly critical area. For operation in harsh environments, it is also important that the electronic components in the robot are safely protected against dust and dirt throughout its service life. Atmospheric overpressure in the housing has proven successful here.

Results / Benefits:

Through the combination of a robot and a three-axis positioning unit with a payload capacity of 750 kg, the system achieves the highest degree of flexibility since it is in a position to deburr different castings from all sides. This significantly increases cycles times for finishing in confined spaces. Further advantages of the new automation solution include: The individual, robot-guided finishing is optimized for the respective workpiece. The quality can thus be improved and kept consistently high, the tools can be protected and a high reproducibility is ensured despite different burr variants. Last, but not least, the new automation solutions have enabled Heidenreich & Harbeck to design jobs in a manner that is more worker-friendly.

Partner

Foundry Corporate News

Topic Automation

Topic Machine mould casting

At Heidenreich & Harbeck, KUKA robots are using contour recognition to remove undefined casting burrs

Reading time: min

[9]