It was a night of good company, good food and drink and, most of all, good castings. Featuring guest speaker, maverick bike & truck racer, Steve Parrish, the evening went with a swing at its new venue, Wolverhampton’s former railway Grand Station.

Central to the evening was the presentation of the three awards, for Innovation, Company Achievement and Component of the Year. Co-presented by Pam Murrell of the Cast Metals Federation (CMF) which organises the event, and Steve Parrish, CMF Vice-Chair Stuart Gregory gave out the trophies to the winning companies. Throughout the evening it was clear that this is an industry which is technically and commercially advancing, providing precision engineered solutions in cast metal and with investment in the people of the future as common themes.

The ‘Component of the Year’ award was won by Sarginsons Industries for its Jaguar Land Rover front sub frame, an 18kg aluminium component previously a ferrous fabricated and welded assembly produced in a remarkable time frame and to exacting requirements. The ‘Company Achievement’ award was won by Macdonald Diecasting, part of the Thomas Dudley Group, for its turnaround of the business and investment in both plant and people. The third award, for ‘Innovation’ was won by Omega Foundry Machinery for their development of the secondary attrition greensand reclamation process.

“All of the entries we have heard about show that the UK cast metals industry continues to adapt and develop in the face of uncertainty,” said Pam Murrell at the end of the presentation. “The industry continues to innovate, invest and succeed, demonstrating great technical and commercial acumen on a regular basis. All this is happening throughout the industry and not just within our exemplars selected tonight and it should hold the industry in good stead as it looks to the future.”

Component of the Year

Winner: Sarginsons Industries, Coventry

Shortlisted: Harrison Castings, Leicester, Maycast-Nokes Precision Engineering, Halstead, Essex and Sutton Castings, Nottingham.

The front sub-frame is for the Jaguar Landrover L551 21MY. The existing part was a ferrous fabricated and welded assembly but the client was seeking an aluminium solution and the challenge was to develop a ‘never been done’ solution in time for the vehicle launch, so there was a 12-week delivery time for prototypes, commencing 6 weeks from delivery of the CAD model.

A three-part pattern design was developed to optimise directional solidification and simulations were done in tandem with the pattern manufacture to enable lean delivery times and patterns were delivered in three weeks. The final 18kg casting has a sand cast variation of 0.1% across the full sub-frame length and over 500 prototype parts have been supplied.

“The whole team at Sarginsons are all very proud of this casting”, said Anthony Evans, Managing Director of Sarginsons Industries. “The component is the product of a team effort and it is the bringing together of individuals and teams with key expertise from throughout the organisation that ensures success.”

Shortlisted in the ‘Component of the Year’ award were: Harrison Castings for a huge diesel engine sump casting measuring over 2 metres long; Maycast-Nokes Precision Engineering for its sand cast wind turbine hub & servo housing; and Sutton Castings for its remarkable one-off cylinder block for a heritage traction engine.

Company Achievement Award

Winner: Macdonald Diecasting, Tipton, West Midlands

Shortlisted: FSE Foundry, Essex, and Voxeljet UK, Milton Keynes.

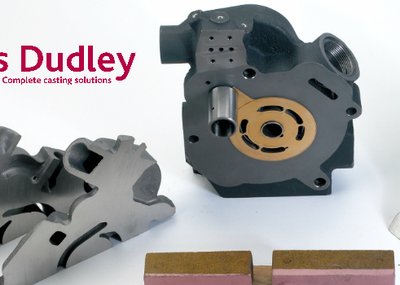

A zinc diecaster in the Black Country and a member of the Thomas Dudley Group, Macdonald Diecasting has been turned around by its management team from a loss-making operation into a company that is rapidly moving forward.

The team has developed a new vision, embedding the company values into the business strategy with greater focus on the company strengths; by 2022 they plan to double the casting output and turnover as part of a systematic and strategic 5-year plan for growth. The company has invested in a new staff development and training programme, improved the working environment and staff facilities, and presents monthly awards. In addition, the company now has a major marketing initiative which is successfully building the brand supported by a presence at major international exhibitions.

Shortlisted were FSE Foundry for its investment in people, refurb & investment programme, and in particular its apprentice programme, and voxeljet UK for its role in helping to revolutionise the industry’s component development processes through 3D printing.

Innovation Award

Winner; Omega Sinto, Peterborough

Shortlisted; CastAlum, Welshpool and Wall Colmonoy, Swansea.

Omega Sinto has developed a technique to increase the reclamation rate of greensand by mechanical means only, known as secondary attrition. The unit uses centrifugal force and pressure during processing removing the binder through friction, rounding the sand grains for better re-bonding characteristics and packing density. To achieve levels of reclamation in greensand of over 90%, the used sand needs to be suitable for core production. As with chemically bonded sands, it had been assumed that the used sand had to be thermally reclaimed by pyrolyzing any remaining binder.

The process can now be used to reclaim both organic and inorganic binders with no damage to the base sand, and leads to increased greensand properties, as well as a 20% reduction in binder content when the reclaimed sand is used for core production. Since thermal reclamation is a high capital and high running cost process, to be able to reclaim mechanically is an important step forward for the industry, saving energy, costs and reducing sand dumping.

The two shortlisted companies were CastAlum, for its research and development programme to replace traditional steel cores with an additive manufactured solution, leading to the development of the ‘perfect cooling channel design’, reduced downtime and a reduction in the problem of solder in high pressure diecasting, and Wall Colmonoy, for its work developing tooling for wax injection patterns suitable for low to medium volume batches in investment casting, using additive manufactured inserts, leading to improved casting quality.