The chromite sand use has been increased in the steel foundries in last two decades. The chromite is used as facing sand due to its high conductivity of heat that avoids the sintering of the sand in contact with the molten metal and so permit to reach a good surface of the castings.

Starting from a mixture in granular size of silica sand and chromite sand, Sogemi plant is able to separate completely the chromite sand from the silica sand.

To reach this purpose Sogemi plant works in three different steps :

- Magnetic separation by means of two high intensity magnetic rolls: in this step we separe the magnetic material, including the chromite sand, that is para-magnetic, from the non magnetic material like silica sand.

- Gravimetric Fluidised density separator: in this step we clean the Chromite sand from different impurities like oxides, by means of the different specific weight of the materials.

- Low magnetic separator: in this step by means of low powered magnetic separator we take off the magnetic impurities that may still included in the Chromite sand.

After these different steps, by means of two pneumatic conveyors , the silica sand and the Chromite sand are transported in the required storages.

Sogemi plant can provide a Chromite sand purity up to 99 %.

Sogemi has realized its first Chromite separation plant in 1994, in one steel foundry Cividale s.p.a that works with alpha-set process, phenolic-alcaline process.

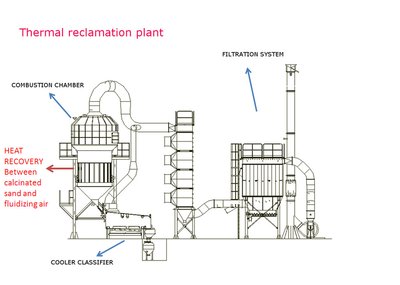

In this foundry Sogemi has combined its Chromite separation plant with its thermal reclamation plant: by means of this combined system the chromite separated sand is thermally reclaimed and re-used and utilized at 100% in the process without adding new chromite sand.

In our experience hence there two ways to utilize the Chromite separation plant (depending on the type of castings production and chemical binder):

- Chromite Separation plant + Thermal reclamation plant : 100% of re-use of Chromite sand

- Chromite separation plant only + 40% new Chromite sand .

After this first plant, with a capacity of 6 t/h, Sogemi has installed many others Chromite separation plants in Europe, Russia and Brazil as well, in different foundries with different chemical process, like polyurethane, alkaline, sodium silicate etc and with different capacity starting from 6 t/h up to 20 t/h.

The last plant in 2013 has been installed in Brazil , in Jundiai SanPaolo Area , in Wier Minerals do Brazil foundry .