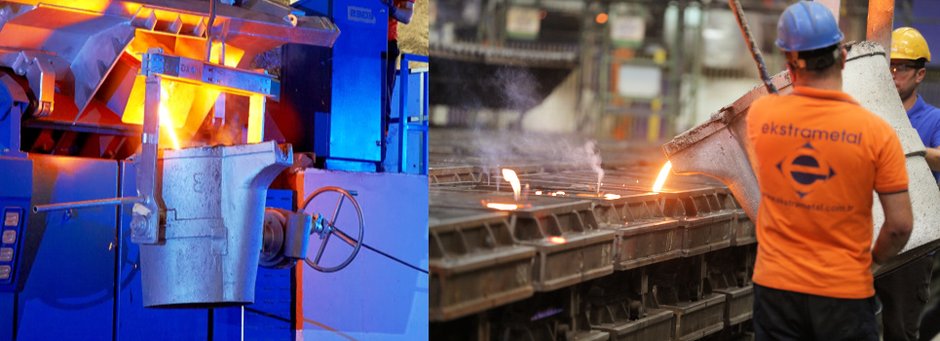

The company, founded in 1987 in an organized industrial zone in Ankara, Turkey, is a middle-sized foundry with a big machining plant providing high quality solutions to its customers at every stage from designing to machining in the production of nodular and grey cast iron parts.

With over 30 years of experience, the company has been producing various parts to well known companies in the agricultural machinery industry, ship building industry, machine manufacturing industry, railway industry, construction industry, hydraulic industry etc upon customers' requests and/or design turnkey projects. Well-known European companies are among the custmers of the Turkish company.

The company has 10.000 tons/year casting and 6.000 tons/year machining capacity and can operate fast and flexible without conceding from its quality for both individual and serial type productions with its modern facilities and production equipments. With nearly 250 employees, the company has been producing machined castings from 10 kg up to 2000 kg.

Furthermore, the company has been providing also the rapid prototyping service for machined castings with using the 3D Printing technology to his customers.The company applies quality control at each stage via hardness test, chemical analysis, ultrasonic test, green, furan and core sand tests, incinerating furnace, digital temperature etc

The company has internationally recognized quality certificates, such as the TS EN ISO 9001:2015 quality certificate by TUV SUD and Part Approval Certificates for Ship Industry from DNV-GL, Bureau Veritas (BVQI), American Bureau of Shipping (ABS) and Lloyd’s Register (LR) & Quality Assurance System Certificate for Material Manufacturer according to Pressure Equipment Directive (PED) 97/23/EC, Annex I, Sec. 4.3 and AD 2000-Merkblatt W0 by TUV NORD.

The company offers manufacturing and subcontracting agreement for companies involved in agricultural machinery industry, ship building industry, machine manufacturing industry, railway industry, construction industry, hydraulic industry etc

The aim of the company is to increase its market share abroad through manufacturing products upon customers' needs and/or design turnkey projects.

Vision

- We want to become the domestic market leader and to have international recognition in grey and nodular cast iron through well-thought-out machining process and high-quality production processes.

- Our motivation is to meet the need of our customers.

Mission

- Through our work we want to make a contribution to the national growth and enhance the standards in the casting industry.

- We want to increase the market value of our company through adding value to our customer’s products manufactured by us with conceptual approach and customer-oriented production.

Our Core Values

- Being Customer Oriented

- Believing in Teamwork

- Having strong quality consciousness to administer and improve existing quality system

- Having respect to experience and supporting intellectual capital and continuous improvement

- Being strictly tied to business ethics and legal principles

- Having environmental conscious

- To focus on solution

- To meet the health and safety standards

Advantages and Innovation

- advanced technology

- qualified staff

- fast production capacity

- on-time delivery

- references from the EU Countries

- internationally recognized quality certificates

- quality control tests at each stage

- 90% of its products are exported to the EU countries

Type and Role of Company Sought

The company offers subcontracting or manufacturing agreement for partners (SMEs or large companies) from ship building industry, railway industry, construction industry, hydraulic industry, agricultural machining industry, machine manufacturing industry etc.

The company can manufacture any product upon customers' requests and/or design turnkey projects. The aim of the company is to increase its market share abroad through reliable and long-term business relationships established.

Locations:

Foundry

Ekstrametal Döküm Izaba ve Mak. San. Tic. Ltd. Şti.

Adress: 1. OSB Karamanlılar Caddesi No:1 Sincan/Ankara

Phone: +90 312 267 0556/57

Machining Facility

Ekstrametal Döküm Izaba ve Mak. San. Tic. Ltd. Şti.

Adress: 1. OSB Büyük Timur Caddesi No:1 Sincan/Ankara

Phone: +90 312 267 0581

Furan Foundry

Ekstrametal Döküm Izaba ve Mak. San. Tic. Ltd. Şti.

Adress: 1. OSB Anadolu Caddesi No:6 Sincan/Ankara

Capacities:

Foundry Capacities:

GreenSand-HWS Automatic Moulding Line

Flask Dimensions: 850x700x350 mm

Induction Furnace Melting Capacity: 3 Ton/hr

Furan Resin Automatic Flaskless Moulding Line

Flask Dimensions: 2000x1400x500 mm

Induction Furnace Melting Capacity: 3 Ton/hr

Furan Resin Automatic Moulding Line

Flask Dimensions: 2200x1800x800 mm

Induction Furnace Melting Capacity: 3 Ton/hr

Pit Moulding

Induction Furnace Melting Capacity: 3 Ton/hr

Machining Capacities:

21 Horizontal Machining Center with 1000x800 mm max. pallet size

10 Vertical Turning Lathe with Ø 1200 mm max. Machinable Diameter

3 Multi-Tasking Turning and Milling Center 610x1080 mm max. pallet size

Vertical Machining Center with 400x720 mm max. pallet size

Vertical Broaching Machine Ø 250

CNC Gear Shaping Machine max. Outer Dimension Ø 650 max. Inner Dimension Ø 550

3D Rapid Prototyping:

Silica Form Furan Sand Printing

1800x1000x700 mm in 18 Hrs