The METEF-FOUNDEQ, the international trade show for metal production will take place in Verona from April 18 - 21, 2012. The die casting business unit of Bühler AG, a company with worldwide operations, will be presenting the latest developments in the field of die casting together with its partner company, BresciaPresse. The focus will be on subjects dealing with energy efficiency in foundries, Lost Core Technology, the efficiency of the Carat two platen technology as well as Structural, the cost-efficient approach to manufacturing structural components and services. In keeping with the motto «Empowering Success», Bühler will show how consistent implementation of solutions reinforces the power of success.

The METEF-FOUNDEQ takes place every 2 years. The trade show in Verona provides over 15,000 square meters of show space and more than 500 global companies use this platform. This makes the METEF-FOUNDEQ one of the largest trade fairs of its kind in the world and it provides its visitors a look at the latest developments in the areas of machines, plant engineering, equipment, products and applications.

Bühler Setting Standards

By supporting energy-efficient production, foundries can contribute to preserving resources and protecting the environment while profiting from reduced production costs. The efficient use of energy is of utmost concern to Bühler. As one of the leading technology partners for the die casting industry worldwide, Bühler supports its customers with modern facilities and production techniques and provides valuable consulting services to ensure stable and trouble-free operations. Bühler sets the standards in terms of productivity, energy efficiency or finding appropriate solutions for manufacturing structural components.

Realizing Potentials in the Area of Energy Efficiency

Every manufacturing process has the potential to optimize in order to save energy. Any improvement, whether large or small, will help increase efficiency. A systematic course of action, in-depth knowledge of the process, and a comprehensive approach are the key to successful implementation. As a leading provider of die casting solutions, Bühler offers a comprehensive spectrum of possibilities for increasing energy efficiency. Customers are provided the opportunity to seek a broad range of advice as to how to realize their potentials.

Lost Core Technology

With its new Lost Core Technology, Bühler will be showcasing an innovative approach to die casting at the Metef, an innovative approach to die casting.

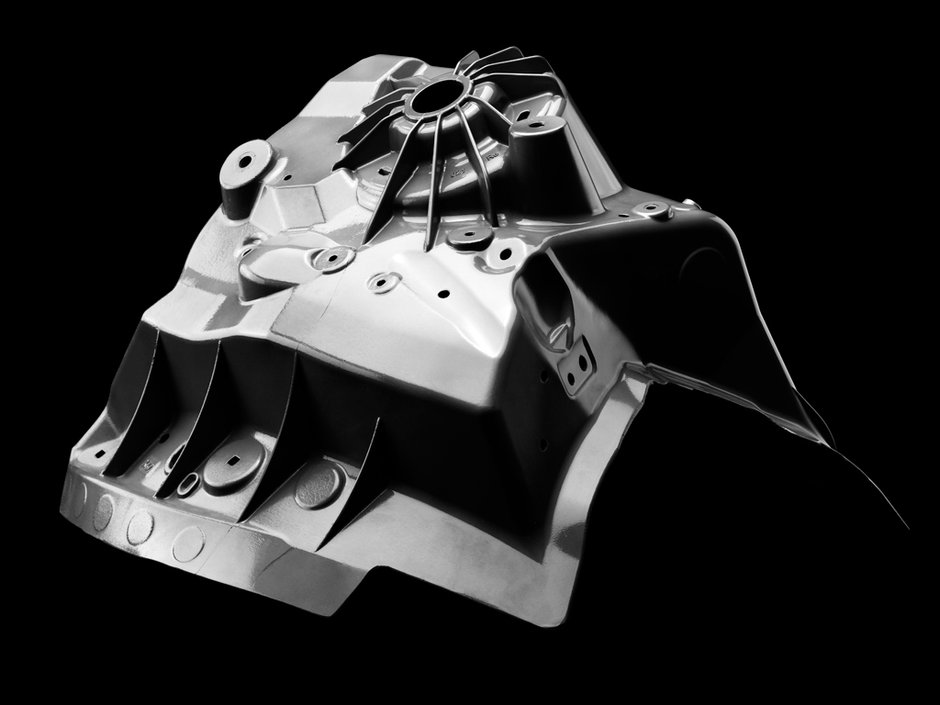

Lost Core creates new opportunities and makes it possible to produce parts that were previously inconceivable. For example, components from the chill cast and sand cast technologies can be substituted, so we can benefit from the advantages of die casting such as savings in materials, shorter cycle times as well as a reduction in follow-up processing. Lost Core also allows for the development of completely new components. The internal design of the die can be made more complex. Aggregating multiple components allows for increased integration of functions and the additional freedom of design makes it possible to create completely new designs of parts.

Carat - A Benchmark for Die Casting

The efficient two-platen die casting machine is considered the benchmark for manufacturing castings of medium to high complexity as well as or structural components. With the three basic models, Lean for lower weights with large surfaces, Compact for standard die casting parts, and Extended for thick-walled parts with smaller surfaces, Carat is well-suited for nearly any application. The Carat closing unit is compelling due to minimal warping, thus guaranteeing a high degree of dimensional accuracy of the parts it produces. The Carat is available in 13 different sizes, ranging from 10,500 to 44,000 kN locking force.

Structural Components for Reducing CO2 Levels

In the automobile industry, manufacturing vehicles of light-weight construction and components is a key criterion for reducing CO2 emissions. Tests have shown that lowering the weight by 100 kg results in a reduction of 8.5 grams of CO2 per kilometer driven. With its «Structural» approach, Bühler supports its customers in the development and production of structural components. This unique range of services not only includes delivery of the appropriate systems technology and support for designing parts and dies, it also includes designing the best process control. This comprehensive approach is rounded out with the on-site implementation, with special attention paid to Bühler specialists providing training for the users.

Bühler is a global leader in the supply of process engineering solutions, especially production technologies and services for manufacturing foods and engineering materials. Bühler has operations in over 140 countries and employs about 8,828 people worldwide. In fiscal year 2011, Buhler generated sales of CHF 2,131 million.

Fiere di Verona, Hall 4, Booth D49.