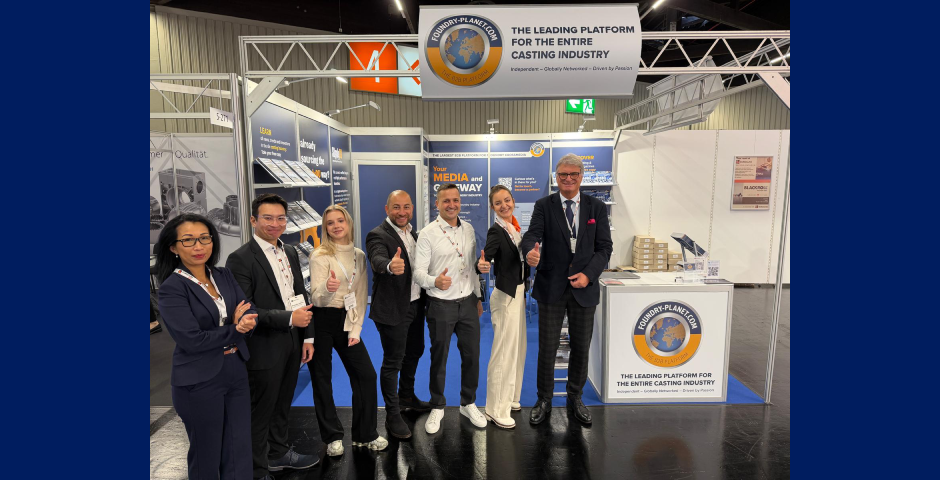

We can only confirm this with our personal impressions. The positive atmosphere at EUROGUSS 2026, which took place in Nuremberg from 13 to 15 January 2026, impressively underlined its role as the leading platform for the international die casting industry.

Positive atmosphere at EUROGUSS 2026: The trade fair, which took place in Nuremberg from 13 to 15 January 2026, impressively underscored its role as the leading platform for the international die casting industry.

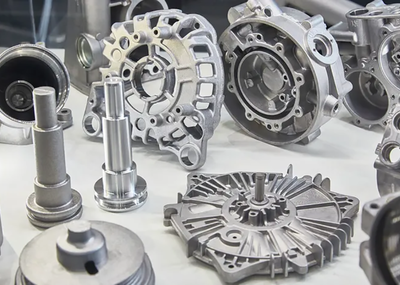

A total of 722 exhibitors from 37 countries presented their capabilities and showed around 15,000 experts how innovatively and effectively the industry is embracing transformation as an opportunity. Die-cast parts are an integral part of modern value creation – in mobility, infrastructure and industrial applications. Aluminium, magnesium and zinc die casting enable the economical series production of highly complex geometries. This makes die casting a key enabler for classic and new applications and market segments, as EUROGUSS demonstrated.

Spanning six exhibition halls for the first time, EUROGUSS was bigger than ever before on its 30th anniversary and impressively demonstrated that it is much more than a classic trade fair: it is a leading trade fair, knowledge platform and central meeting place for an industry that is realigning itself technologically, structurally and strategically.

Phuong Anh Do, who is responsible for the strategic and conceptual development of the event brand, is impressed by the exhibition: "Three days of live die casting, an all-round positive atmosphere – I am thrilled to see how the industry is working together to shape the future of die casting in Europe. EUROGUSS is a successful concept that brings together the entire die casting value chain, including die casting foundries as drivers of innovation."

Satisfied exhibitors and visitors

At EUROGUSS 2026, 722 national and international exhibitors presented their products and services along the die casting value chain to an interested trade audience. Almost one in three exhibitors and around half of the approximately 15,000 visitors came from abroad. Numerous visitors travelled to Nuremberg from Italy, Austria, Poland, Czechia, Turkey and Switzerland in particular. But there is also immense global interest in the European market from North America, India and Asia.

In addition to OEMs and Tier 1 suppliers, visitors also included manufacturers and users from the electrical engineering, energy technology, DIY, sanitation, home and garden, medical technology, communications technology, aerospace and lifestyle sectors. EUROGUSS is characterised by technical excellence, engineering expertise and process know-how. This is evidenced by the numerous decision-makers, development managers and investment decision-makers on site. ‘We are very satisfied with the quality of the visitors. We had high-ranking decision-makers and a very good response at our stand,’ confirms exhibitor Aulbach Pressenbau. Kira Jülicher, Managing Director of COURS GmbH & Co. KG, sums up EUROGUSS in one sentence and praises the atmosphere: ‘Metallic innovations from across Europe in one place. I am impressed by the numerous stands and exhibition sections, how much creativity the companies at EUROGUSS have shown and how open they are to new contacts – both at supplier and customer level.’

EUROGUSS as a pioneer for future business

Whether megacasting, AI-supported manufacturing, material innovations, lightweight construction, quality assurance, highly automated production cells or recycling: for three days, EUROGUSS focused on business related to established and new fields of application for die casting.

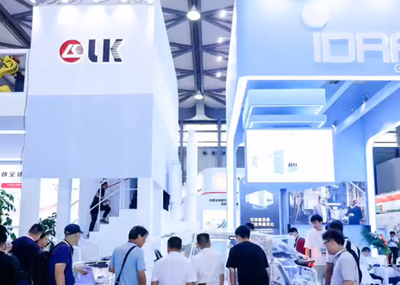

Megacasting: Megacasting represents a significant change in die casting technology and enables the production of extremely large and complex components in a single operation. This is achieved with machines that exert a clamping force of over 6,000 tonnes. By using massive high-pressure die casting machines to produce large, single-piece aluminium structures, megacasting replaces conventional manufacturing methods in which hundreds of smaller components are welded together. This approach offers significant opportunities to reduce the number of parts, streamline assembly and improve cost efficiency and structural performance, particularly in automotive applications. This technology has the potential to promote the rapid advancement of European brands and ensure their competitiveness in a challenging market environment. Megacasting is expected to expand into new vehicle segments and industrial applications due to continuous innovation in simulation, automation and digitalisation, hybrid manufacturing approaches, machine size, alloy development, tooling and more sustainable recycling strategies.

Digitalisation & AI: Increasing quality and stability requirements in die casting require continuously adaptable, data-supported process control. AI-based methods create new opportunities in quality assurance and make processes more efficient – especially in megacasting. ‘The focus is not on the technology itself, but on measurable impacts: reduced downtime, less scrap, improved energy efficiency and faster learning across processes and locations,’ notes Simon Schmidt, project manager at the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM). EUROGUSS used practical examples from industry to show how processes are being digitised and how creativity is being used to develop new solutions. Michael Heuser, Senior Scientist at IFAM, notes a high level of automation in die casting and emphasises the advantages: "The real benefit of using AI lies in data refinement: We are moving away from pure monitoring towards proactive, AI-supported process optimisation in real time. In the future, AI will autonomously trim casting processes for maximum resource efficiency and minimum scrap rates. This will make digital transformation the decisive lever for the competitiveness and sustainability of the entire die casting industry."

Rheocasting: Trade fair visitors were able to experience innovative die casting technologies such as the rheocasting process up close and learn how this casting technology overcomes the limitations of conventional processes and opens up new possibilities for lightweight construction, material efficiency and industrial applications by producing components with higher strength, low porosity and excellent surface quality. The demand for lightweight, high-performance and sustainable components is growing, particularly in the automotive, aerospace and e-mobility industries – and rheocasting provides the right solutions. Fabian Niklas, founder and managing director of CASTING-CAMPUS GmbH, explains: “Rheocasting, an extension of the die-casting process using a semi-solid, makes it possible to significantly expand the range of applications – with properties that offer a unique selling point. The process technology is available; all that is needed is to adapt the mould to the process and the alloy. Once established, this market offers excellent margins.”