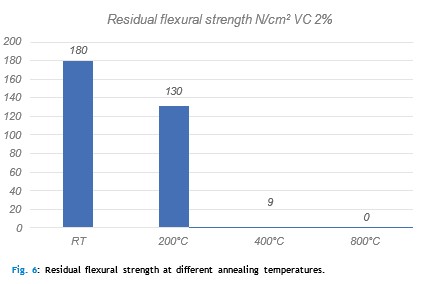

In order to substantiate this subjectively positive behavior with figures, the decoring behavior should be evaluated on the basis of the residual bending strength:

-

For this purpose, bending bars were produced which were exposed to the test temperature for 5 min 24 h after production and tested 2 h after removal from the furnace.

-

The test temperatures were 200, 400 and 800 °C.

The results shown in figure 6 confirm the positive properties already evident from the casting tests in this direction. The test temperature of 400 °C is intended to represent the trend in the area of aluminum casting, while the temperature of 800 °C stands for iron casting. It can be concluded from this that the inorganic binder system pre- sented exhibits decomposition and decoring behavior similar to the PUR cold box process.

Examples from practice

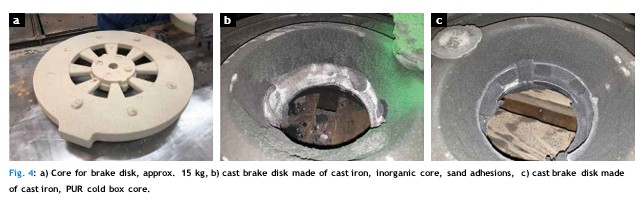

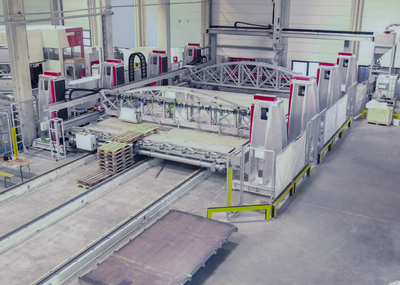

To date, cores with the inorganic binder system presented have been produced and successfully used in a whole series of foundries. The cores shown in figure 7 are exemplary for the field of iron casting. The range extends from outer cores for core packages to the afore- mentioned brake disk core and the fili- gree core for valve casting. The area of non-ferrous casting, which has not been the focus of this article so far, is impressively illustrated by the example shown in figure 8. Here, too, the range of possible applications extends from simple cores, e.g. for intake manifolds, to the highly complex core of a cylinder head. The examples shown are used in the areas of copper and alumi- num casting.

Summary

The presented inorganic binder system based on water glass is an alternative to the PUR cold box process that can be used in iron and steel casting. The liquid one-component binder is dosed less than comparable binder systems: the binder quantities used to date are between 1.5 and 2.5 %, but can also be increased if required.

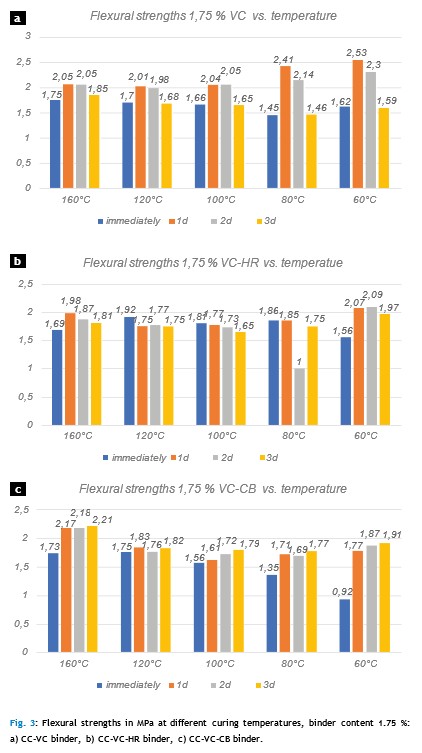

The single-component system facili- tates binder dosing on the core shooter, and the desired strengths are ensured by comparably higher specific strengths. The curing of the manufac- tured cores takes place via 160 °C warm gassing air. The core production tool is not heated. When selecting the core box material, care should be taken to use thermally resistant plas- tics. Core boxes made of metal (alumi- num or steel) offer advantages in terms of shorter cycle times.

If particularly dry air is used, curing can be achieved at lower temperatures. The binder system can of course also be used in the warm or hot box process. The fact that veining only occurs in exceptional cases with the inorganically bonded cores is certainly a welcome advantage in the fettling shop.

The residual strength and decoring behavior is very similar to that of the PUR cold box process. In addition to the binders designed for iron and steel cast- ing, variants for aluminum or copper casting are also available.

www.peak-giesserei.de Excerpt from ‘GIESSEREI’ (2024), issue 2, pages 43–47. © DVS Media GmbH, Düsseldorf