Preparations are now underway and are progressing well to have the second cylinder cast in the near future.

Premier Patterns in Smethwick produced the polystyrene patterns and then these were dispatched to the Shakespeare Foundry in Preston where they were to be cast.

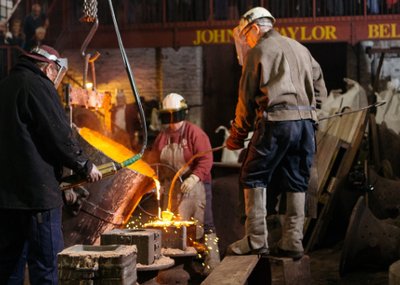

However, sadly, the company went into receivership before the patterns could be cast, so later enquiries identified a specialist who had previously worked with polystyrene patterns to produce locomotive cylinders. Boro Foundry were contracted to deliver the castings.

After a tough year with the pandemic, good progress has been made. The cylinders have been redesigned to fit into the Network Rail loading gauge, similar to the design of 6024 King Edward I.

4709’s Chief Engineer, Paul Carpenter explains; “Premier Patterns in Smethwick produced the polystyrene patterns, which were completed and inspected during February 2020, then dispatched to the Shakespeare foundry in Preston for casting. This foundry had successfully cast locomotive cylinders using poly patterns for several other projects, but luck wasn’t with us – on the day our patterns arrived at the foundry, the company was placed into receivership.”

“We were fortunate to be able to extricate the patterns from the receiver and a search was started for another foundry. We quickly discovered that in our modern manufacturing world, the number of suitable candidates is significantly less than a century ago, when 47xx cylinders were first being cast.”

“We contacted every foundry currently producing cast iron products, only to discover little enthusiasm for the project. Either the sheer size and volume of the casting or concerns centered around the specialist knowledge required to work with poly patterns, caused most to decline to bid for the contract. Months were spent in detailed discussions with one foundry, only to have them decide at the last moment that they too could not deliver the castings” adds Paul.

“The success of this project represents an important development for the casting of locomotive cylinders for our heritage world. Without doubt, Boro Foundry are now the centre of excellence for this specialist work and we are very grateful to both them and Alan Boulton for their commitment to the challenge. We are also very grateful to our good friend Mike Solloway, who on our behalf, has made regular site inspections. His experience and knowledge from casting cylinders for his own engine has been invaluable,” concludes Paul.

The 4709 group’s treasurer, Richard Croucher adds; “Bob Meanley was invited to produce drawings for the cylinder block redesign and his drawings would surely have delighted Churchward himself. In addition to his work as a first-class locomotive engineer at Tyseley Locomotive Works, Bob is also an excellent draughtsman. On top of his work on the cylinders, he has also produced detailed drawings to allow new front and rear cylinder cover patterns to be made.”

“The pattern for the second cylinder block is now being prepared at Boro Foundry and a date for the cast is anticipated shortly. Once both blocks are completed, they will stress relieved in a furnace before being delivered to our machining specialist, who is ready to start work,” adds Richard.

Source: Michael Holden, railadvent.co.uk