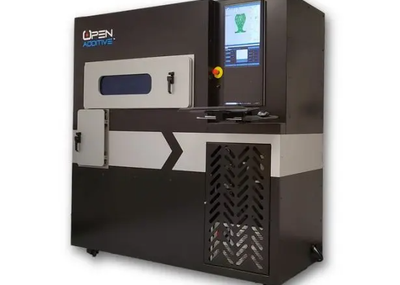

This investment allows Franklin Bronze to produce rapid prototype parts and short runs of investment castings.

“The addition of this 3D printer to our facility allows us to quickly prove out design changes without needing to alter the tooling each time. For instance, making a gating change can be proved before cutting into the tool”, states Neil Kruse, Senior IC Process Engineer.

“We are looking forward to working on trials and iterations for new and existing parts with our customers in a more efficient manner. Additionally, working with customers that have an intricately designed part.”

The Laser SLA 3D Printer is able to construct parts quickly and accurately with high precision and resolution.