General Chemical is a pioneer and worldwide supplier in supplying water based & solvent based fast drying temporary protective coatings. We have been a proven worldwide supplier for over 25 years for various substrates such as aluminum, ferrous and non-metallic surfaces. We have a robust of amount of coatings in the market to fit your company needs. Our products can be applied as liquid, sprayed, rolled on, or brushed on to form a dry form fitting film that can be peeled with ease when required. This prevents damage on any desired surface if applied properly.

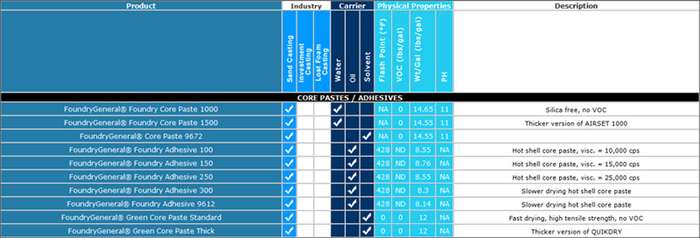

We have sales people available who speak English, Korean, Spanish, French, Italian, Japanese, and Hindi. We have sales people stationed in the U.S.A., Canada, United Kingdom, South Africa, Philippines, Taiwan and Japan. Our FoundryChem® Core Pase and Hot Shell Adhesives are available in both water based and oil based formulations.

For solutions and additional information on how FoundryChem can help you resolve today’s every changing manufacturing problems, call us directly at 1-866-623-5600

In the Shell or Hot Box Process, resin bonded sand or a sand/resin mix is placed on a heated metal pattern for a short period of time to form a partially hardened shell. The bulk of the sand mixture inside the shell is removed for further use and then the pattern and shell are then heated to further polymerize the sand/resin mix. The shell is then removed from the pattern. As with the No Bake Process, these shells are broken or are sectional cores and require an adhesive in order to piece them together. Hot Shell Adhesives containing a thermosetting resin are typically used for this. These Hot Shell Adhesives are generally applied to the hot shell cores and molds and typically utilize a liquid carrier that does not boil or dry out rapidly, allowing the operators sufficient time to position the pieces.

###COMPANY_LINK### <link record:tx_browserdirectory_directory:4875 internal-link>![]() General Chemical Corp.

General Chemical Corp.