The proprietary and patented magnetic separator conveyor from Bär exploits simple laws of physics in order to achieve high cleaning performance with minimal power consumption

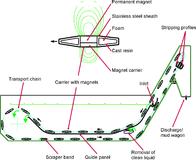

| Schematic drawing of a magnetic separator conveyor from Bär+Co. The laminar flow and minimal speed differential between the magnetic systems and liquid flow ensure that all liquid phases remain in the magnetic system's zone of influence for a long period of time. This results in very good separation performance and efficiency. |

Bär+Co. Anlagentechnik GmbH of southwestern Germany will exhibit an energy-efficient coolant cleaning system at their booth at the EMO trade fair in Hanover from September 19 to 24 (Hall 7, Booth C06). The proprietary and patented magnetic separator conveyor from Bär exploits simple laws of physics in order to achieve high cleaning performance with minimal power consumption. These machines have been continuously developed for more than 10 years and are in service around the world.

Magnetic separator conveyors (MSC) from Bär handle virtually any coolant-cleaning tasks when processing ferritic materials like steel, gray cast iron, and Fe-sintered metals. Each machine is adapted for a specific application. But since Bär machines are constructed from standardized components, they are available quickly. Depending on specific requirements, one system may supply a single machine or serve as a centralized unit for an entire production area.

The MSC utilizes a patented, highly-efficient design that consumes a very low amount of energy in operation. Drive power is only about two-percent of the power consumption of conventional systems with the same conveyance and separation capacity. For example, a large system with a throughput volume of 5000 L per minute needs no more than 0.74 kWh of power. Operators of these machines save even more with years of maintenance-free operation and the ability to separate out contaminants without filter consumables.

"Magnetic separator conveyors from Bär+Co. are significantly more efficient than alternative technologies. The patented design ensures that even minimally magnetic contaminants are reliably removed from the liquid," according to Armin Bär, who, together with Siegbert Schroff, is the second generation of the Bär family to lead the company. Since its founding, Bär+Co. has delivered approximately 5000 coolant-cleaning systems, chip conveyors, and grinding swarf presses. The tool machine and automotive industries represent the largest customer groups. Bär+Co. installations are currently in service in all major industrialized countries, including China, Korea, Malaysia, South Africa, and Brazil.