Mercedes-Benz is taking the next step in the modernisation of Untertürkheim, its lead plant for the powertrain production worldwide. The company and the works council have updated the transformation plan and agreed upon initial initiatives for electric mobility, in line with plans to safeguard worker jobs at the site.

“We shape the future in the powertrain production of Mercedes-Benz Cars by establishing ground-breaking production technologies in the lead plant Untertürkheim. This is a further step to ensure our competitiveness in the new age of electric mobility,” says Markus Schäfer, Member of the Divisional Board of Mercedes-Benz Cars, Production and Supply Chain Management.

Part of the agreement is a new e-technology centre where prototypes for electric powertrains will be constructed. The so-called ‘E-Technikum’ will become the ramp-up factory for key technologies. The plant will also make first steps in the assembly of electrified powertrain modules and start producing components for electric vehicles.

The agreement also paves the way for further capacity expansion of combustion engines, e.g. for the new generation of high-efficient in-line engines. The production of engines, transmissions and axles will remain an integral part of the Untertürkheim product range. The foundry at the site Untertürkheim will also produce components for future engine generations.

To make space for electric mobility components, products such as fuel system components and turbine housings will be relocated. The employees affected by the relocation will be offered equivalent jobs primarily in similar areas or in the new fields of electric mobility.

Untertürkheim: Mother powertrain plant

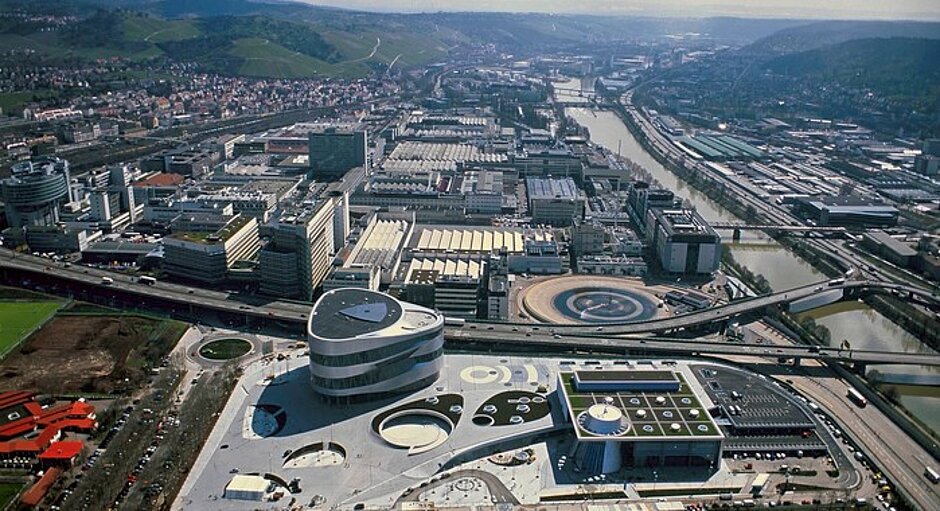

The Mercedes-Benz Untertürkheim plant, in operations since 110 years, is the lead plant in the global powertrain production and the home of the Daimler headquarters. With more than 19,000 employees, the plant produces engines, axles, transmissions and components. The tradition-rich plant is a high-tech location and a centre of competence for high-efficient engines, hybrid powertrains and the production of fuel-cell systems.

The R&D facility is also located here with a test track. The site comprises of six facilities which are all located in the Neckar Valley next to Stuttgart. While Untertürkheim and Bad Cannstatt produce engines and also host forging activities, the transmissions are produced in Hedelfingen. The axle production and the foundry are located in Mettingen. The training centre is based in Brühl, the flexible production facilities are in Esslingen.

Mercedes-Benz and its worker unions have already initiated several transformation plans for the German powertrain plants, targeting higher flexibility and efficiency. The Berlin plant has been transformed into a high-tech location for components featuring technologies for CO2 reduction. In future, the Mercedes-Benz Hamburg plant will also produce electric components in addition to the traditional portfolio comprising axles, axle components, steering columns, and lightweight-construction structural components. Batteries for electric Mercedes-Benz and smart vehicles are produced by Deutsche Accumotive, a fully owned Daimler subsidiary, which is part of the global powertrain production.

Source: autocarpro.in

×