When it comes to vehicles, every gram counts if ambitious targets in terms of fuel economy and CO2 emissions are to be achieved. That is why Continental, the international automotive supplier, has developed a new fixed-type caliper brake for medium-sized passenger cars. Compared with the fist-caliper brakes widely used at present, this new design can save up to 1.5 kg per wheel. To enable this progress to be made with the highest level of acoustic comfort, Continental has applied the knowledge it has gained over many years of experience with the FN fist-calipers to the development of its new fixed-type caliper brake. The new aluminum monobloc brake caliper features drawn brake pads and is fundamentally much more robust in terms of brake squeal – previously a known problem with fixed calipers. "We are helping vehicle manufacturers to further reduce the CO2 emissions on new models. Weight is a key factor in this respect. At the same time, light-weight design must not be allowed to create problems in other areas. In order to prevent squeal on fixed-type caliper brakes, we have used our experience with fist-caliper brakes to come up with an innovative fixed-type caliper design", said Dietrich Golz, Head of Development for Wheel Brakes at the Hydraulic Brake Systems Business Unit at Continental's Chassis & Safety Division.

The new fixed-type caliper is primarily designed for the front axle, but can also be scaled for the rear axle. Based on this concept, the company is also considering developing a solution for the high-performance segment.

A wide variety of requirements for disk brakes

Disk brakes are the backbone of active safety and must therefore meet extremely high standards in terms of reliability and efficacy. In addition to their core function, weight, acoustic comfort, pedal feel and appearance also play a significant role. The more demanding requirements become in terms of fuel efficiency, the greater the importance placed on factors such as weight, for instance. This explains why the demand for fixed-type caliper brakes is increasing in markets around the world.

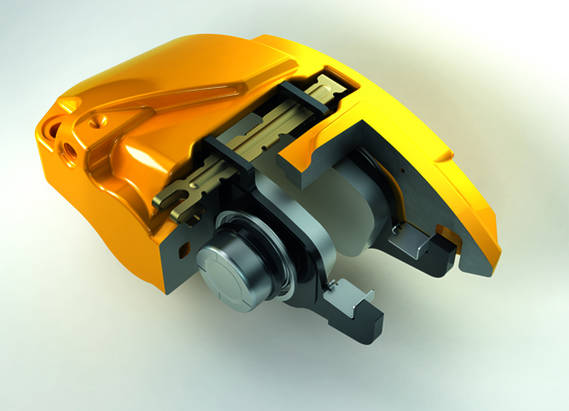

Unlike the fist-caliper brake, the fixed-type caliper has brake cylinders on both sides of the brake disk. The new 4MF fixed-type caliper brake (four pistons in a monobloc fixed-caliper housing) therefore has four brake cylinders. The brake caliper is inherently rigid and does not have to transfer any reaction forces from the side with the brake cylinders to the opposite side of the disk. Fixed-type calipers can therefore be installed in the area around the solid bridge straddling the brake disk, but also at the sides of the caliper with reduced thickness. The technical benefits of the fixed-type caliper include residual brake torque when the brake is not actuated: the gap between the brake pads and the surface of the brake disk – known as clearance – can be made smaller and more even with a fixed-type caliper. This is exactly what has been achieved with Continental's new fixed-type caliper. The brakes are extremely responsive and the pedal feel is precise.

'Transfer of DNA' from the floating caliper brake

For all its advantages, the fixed-type caliper brake has always had an audible weakness: as its frame is rigid, it cannot dampen any vibrations. Fixed-type calipers therefore tend to squeal when the brakes are applied. In order to eliminate this unwanted side effect, Continental has used simultaneous engineering to transfer the characteristic shape of the drawn brake pads to the fixed-type caliper. This required a comprehensive understanding of the kinematics of drawn pads. On the new brakes, the brake pads are not held in place by individual bolts with cushion deflection, but by a central retaining spring with integrated pin lock. In conjunction with the shape of the pad backing plate designed to support the pad, this greatly reduces the vibrational energy when braking.

A brake you'll want people to see

The new 4MF fixed-type caliper brake offers visual benefits, too. Firstly, the retaining spring that holds the brake pads in place is virtually invisible to the observer. Secondly, the new design does not require external brake line tubing. When producing the caliper, this connection between the inner and outer brake cylinders is cast into the aluminum alloy of the caliper in the form of special connecting conduits. This makes the fixed-type caliper visually more appealing and prevents dirt from collecting in this area. The vehicle manufacturer also has greater freedom to adapt the external shape and surface of the brake in line with its brand character. This is becoming increasingly relevant, as more and more vehicles are now being equipped with large wheels that have fewer spokes and offer a clear view of the brake.