A new, lean vacuum impregnation system is providing significant economic benefits for a Japanese automotive OEM in the USA. The Continuous Flow Impregnation (CFi) system, from Godfrey & Wing, has been installed as part of a fully automated engine manufacturing line and is capable of impregnating a single aluminum cylinder block in less than 98 seconds. While the efficient cycle time allows for complete integration on the machining line, the effectiveness of this proprietary impregnation process has delivered a First Time Through (FTT) acceptance rate of over 99%.

The operational savings realized from the CFi vs traditional impregnation equipment have been demonstrated to be in excess of $1,100,000 USD annually.

The CFi has raised the bar in the vacuum impregnation industry to new levels. Combining efficient cycle times with excellent sealing performance (guaranteed to seal micro porosity) and high performance post cleaning the CFi provides a lower treatment cost per block along with tangible environmental benefits. In addition, the CFi operates without direct labor, significantly lowering the hours/unit production cost which is extremely important to the automotive OEM.

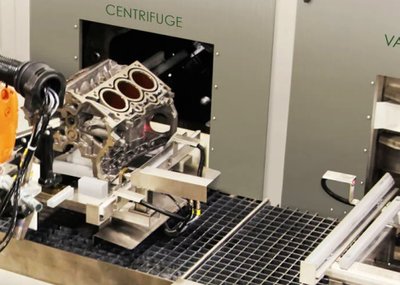

The CFi system takes a single fully machined cylinder block straight from the production line and using a robot, automatically passes it through a four stage vacuum impregnation process. The process components are a Dry Vacuum Pressure (DVP) impregnation chamber using a low viscosity sealant, a centrifuge to recover surplus sealant for re-use, a water wash /rinse stage and a hot water cure stage to solidify the sealant inside the casting porosity.

As a result of this very effective process, impregnated cylinder blocks are impervious to the passage of gas or liquids which could otherwise result in leakage during service leading to engine failure and expensive recalls.

Capable of operating 24 hours a day, 7 days a week across three shifts and producing over 250,000 cylinder blocks per year, the CFi is an integral part of the OEM’s operation.

A feature of the CFi system is the ability to process singular parts such as cylinder heads, blocks, transmission cases or trays of smaller parts such as fuel injection pumps, air conditioning compressors and power steering housings in just a few seconds. This benefits handling and a seamless integration with other manufacturing operations, as well as requiring significantly less floor space than conventional impregnation systems.

auch verfügbar in: <link record:tt_news:12566 internal-link>![]()

![]()

disponibile anche in: <link record:tt_news:12568 internal-link>![]()

![]()

disponible dans: <link record:tt_news:12567 internal-link>![]()

![]()

###COMPANY_LINK###<link linktosingle> Godfrey & Wing GmbH