Albert Handtmann Metallgusswerk GmbH & Co KG has further developed casting processes within the die-casting process, enabling the production of complete aluminium wheels for the first time. The new light performance wheels weigh up to 20 per cent less than conventional low-pressure die-cast wheels. The 360° solution provider is thus opening up a market segment that was previously unattainable in die casting and setting new standards in the industry. Automotive and wheel manufacturers, fleet operators and end customers benefit from a better carbon footprint, increased driving dynamics and greater design freedom. In battery-electric vehicles, the range is also noticeably increased. The new aluminium wheels will celebrate their premiere at this year's Euroguss in Nuremberg and will be ready for series production in the course of 2026.

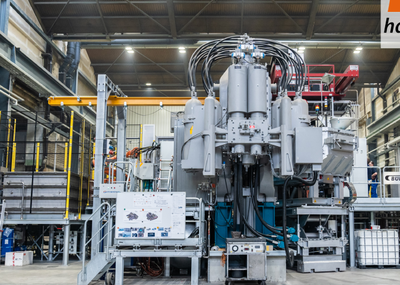

The new casting system enables the production of aluminium wheels using die-casting for the first time and demonstrates Handtmann's comprehensive development expertise in the light metal industry. The entire process, from the initial idea to the design of the casting system and production, was carried out in-house. The wheel blank is cast in series using the die-casting process at Handtmann. The post-casting processes, such as machining, painting and all quality assurance processes, are carried out at the partner company Cevher Group. The Cevher Group has decades of experience in the wheel industry. Both partners tailor the entire process to the needs of the automotive industry. ‘With the introduction of this technology, we are opening up the product field of automotive wheels for die casting and at the same time creating the basis for transferring the process to other components in the future. In doing so, we are setting new standards in the light metal and automotive industries,’ says Dirk Seckler, Co-CEO of Handtmann Leichtmetallguss.

HPDC as a key technology for efficient wheel production

At the heart of the innovative casting process is High Pressure Die Casting (HPDC), which has proven itself in the efficient production of large series. Handtmann is using this high-performance die-casting technology for the first time to manufacture complete aluminium wheels, a product segment that was previously reserved exclusively for low-pressure die casting.

In HPDC, liquid aluminium is injected under very high pressure into a precisely designed mould in a very short time and solidifies there under applied pressure. In this way, complex, thin-walled components with high dimensional accuracy and excellent surface quality can be produced in large quantities. The combination of short filling times, high clamping force and automated processes enables efficient series production. The components are produced with a near-net shape, which reduces the need for machining. For Handtmann, HPDC thus forms the basis for the highly productive large-scale series production of structurally relevant aluminium components such as wheels. At the same time, the process supports OEMs and wheel manufacturers in reducing CO2 emissions and developing aerodynamically optimised designs.

New design possibilities for OEMs

For car manufacturers and wheel producers, reducing CO2 emissions is a key focus in both the manufacture and operation of vehicles. The new die-cast wheel meets these requirements by reducing air resistance thanks to its lower weight and aerodynamically optimised geometries, thereby increasing the range of electric vehicles in particular. "Thanks to the new design freedom in HPDC and the minimal warping in die casting, designs can be implemented that were not possible with conventional processes. This will delight car enthusiasts and designers alike. In addition, the often additional aero cover is no longer necessary, which further reduces weight and costs," says Andreas Würzer, Head of Technical Development.

Advantages for end customers and fleet operators

End customers benefit from a light performance wheel that noticeably improves handling thanks to lower unsprung masses. The combination of attractive design, improved driving dynamics and sustainable manufacturing enhances the overall performance of the vehicle. Fleet operators, for example in logistics, car sharing or corporate mobility, also benefit from the optimisation effects in terms of efficiency and cost reduction. This is because the improved CO2 balance can be used for certificates and sustainability reports due to lower fuel and energy consumption during operation.