Shot blasting of engine blocks, weighing 700 kg, within 50 second cycle times

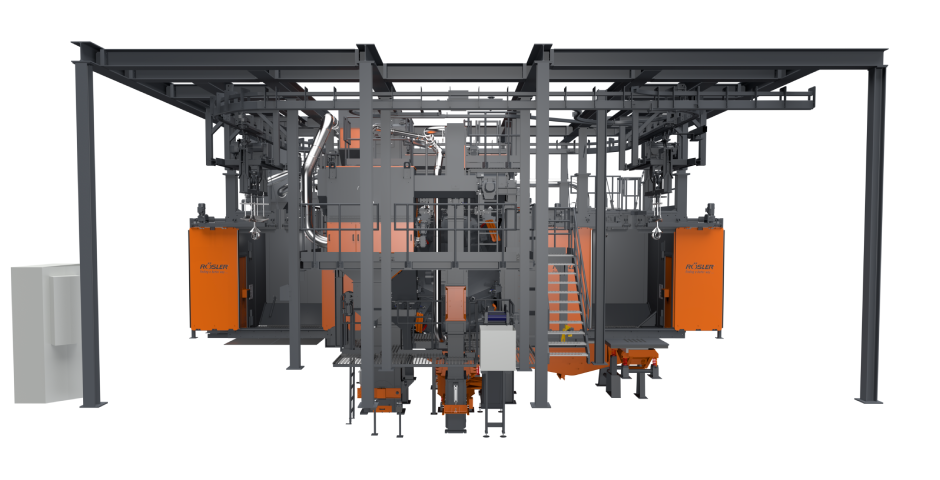

Such a shot blast system will be installed at a renowned German iron foundry for fully automatic deburring and surface homogenization of engine blocks for utility vehicles. The work pieces are produced with new, innovative casting technology. A key functional demand for the engine block blast machine (RMBS), including the work piece handling, was that it must be able to process work pieces weighing up to 700 kg. Furthermore, the entire cycle time of 50 seconds, of which 20 seconds are actual blasting time, must not be exceeded. Such time constraints require an extremely intensive shot blast intensity and quick work piece handling by robot. To ensure high equipment availability with minimal downtimes for maintenance, the entire machine design must be highly wear resistant. For coping with these challenges Rösler decided to implement an innovative design concept. The blast chamber is made of sturdy 8 mm thick manganese steel and is additionally lined with replaceable wear plates. In an entirely novel approach the bottom of the blast chamber is filled with wear resistant steel balls. These prevent the migration of steel flashes (flakes) into the media recycling system. Another advantage is that the steel balls are deflecting the blast media much better than a flat surface increasing the overall wear-resistance.

The equipment manufacturer also took a new approach with the six direct-drive blast turbines installed in the engine block blast machine. Each of the turbines has an installed power of 45 kW. Usually, if their power exceeds 37 kw, turbines with indirect drive are utilized. Compared to direct-drive units they require a lot more space. Moreover, turbines with indirect drive offer a somewhat lower performance, therefore increasing energy consumption. For these reasons, direct-drive turbines were the preferred choice. Based on the utilized blast media with grain sizes of up to 1.6 mm, the Rösler engineers decided to install the powerful “Evolution” turbines. These are equipped with more powerful motors and re-enforced bearings. A specially designed support structure allows placing them on the roof of the blast chamber. Each turbine contains eight straight throwing blades throwing up to 500 kg of blast media at the work pieces every 60 seconds.

The high weight of the engine blocks posed a particularly difficult challenge for the robotic handling of the work pieces. A manipulator, able to carry up to 700 kg, had to be found. In addition, it must rotate the work pieces in front of the blast machine and tilt them by 360 degrees to remove residual blast media trapped inside of the engine blocks. For this purpose, the robot is equipped with a “lightweight” gripping system that allows safe pickup and handling of the different engine block types.

At the center of the RMBS shot blast system is a specially developed manipulator-gripper with two gripper jaws. This setup allows the simultaneous processing of several small work pieces or one large engine block. A special transport system transfers the raw castings from the foundry directly to the shot blast machine. At an alignment station the engine blocks are precisely positioned for pickup by the robot. After pick up the robot transfers the work pieces to the manipulator-gripper in the blast chamber. During the 20 second blast cycle the gripper rotates the work pieces (one large or several smaller engine blocks) below the blast media stream. After completion of the blast process the robot removes the work pieces from the blast chamber, tilts them and places them on a transport system for transfer to the next manufacturing station.

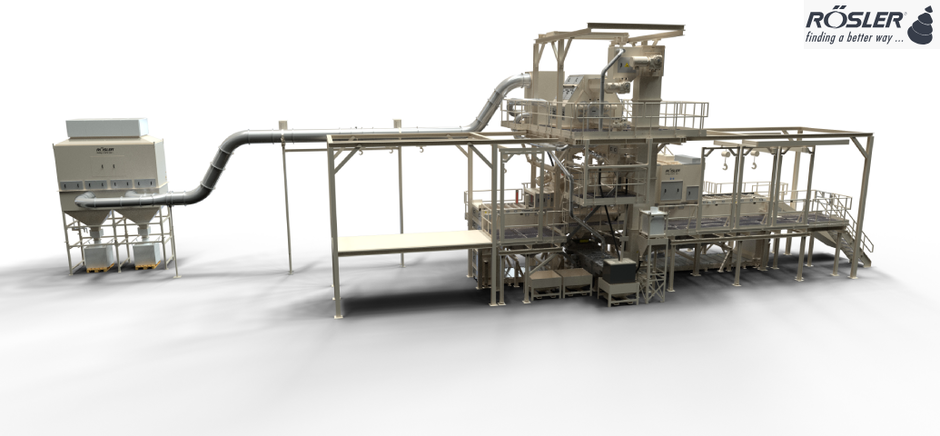

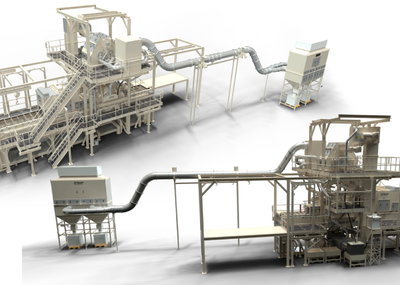

Shot blasting of delicate work pieces as entire batches or in continuous flow mode

For cost-efficient processing of delicate work pieces, prone to nicking and scratching, Rösler offers highly effective solutions, namely spinner hanger and wire mesh belt blast machines. Technical details like throughput capacity, number of turbines and their power as well as wear protection, can be adapted to the individual customer requirements.

Spinner hanger blast machines are suitable for a wide range of different blast applications and are characterized by a compact, space saving design. They are used for treating delicate parts that must not tumble over each other, components with complex shapes as well as heavy and large work pieces. Several work pieces can be processed in batches, or single castings can be placed on a work piece carrier and transferred into the machine. In the blast chamber the carrier is rotating and oscillating at a speed precisely adapted to the work pieces. This ensures that the blast media reaches all surface areas for absolutely repeatable, consistent results.

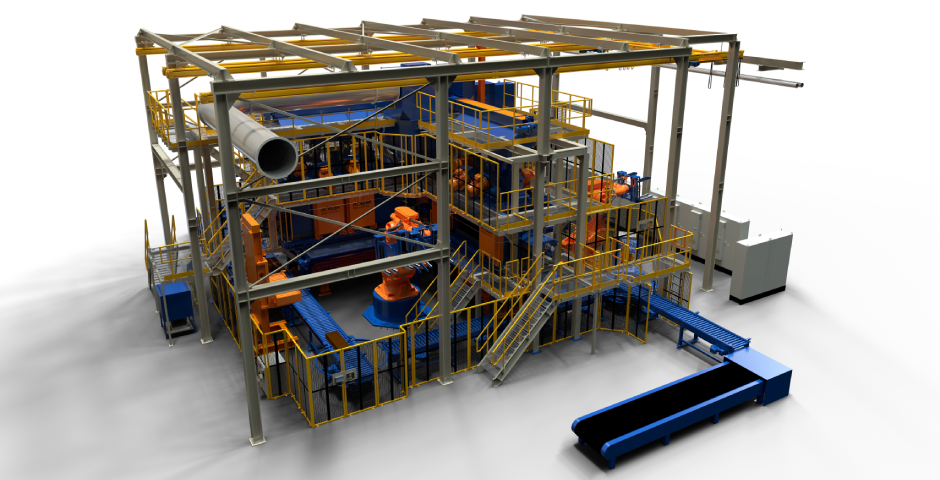

Wire mesh belt blast machines are ideal for all-around reliable shot blasting of mainly long, flat and somewhat larger components. At the center of these blast systems is a wear resistant wire mesh belt transporting the work pieces through the machine. The position of the turbines around the blast chamber is adapted to the work piece shape and size. This guarantees perfect results, even for the most complex work pieces. Because of the special belt arrangement the lower turbines only blast through one belt layer, which minimizes shadowing, the so-called “cover effect”.