Working with Elementum 3D, the firm has formulated a highly-resilient metal that remains lightweight yet exhibits excellent thermal resistance properties. Having now qualified the material for 3D printing, BEAMIT says that it performs “better at both room and high temperatures than other alloys,” making it ideal for producing durable chassis, suspension and engine parts with motorsport applications.

“The 2024 alloy perfectly embodies what we mean when we talk about the integrated development of the AM process,” said Andrea Scanavini, Group General Manager of BEAMIT. “It has been made possible by a multidisciplinary research group and access to unique machinery to study and apply top-level precision processes.”

“TO ACHIEVE A RESULT LIKE WE DID IN THIS CASE, IS DECIDEDLY EXTRAORDINARY.”

BEAMIT’s material ambitions

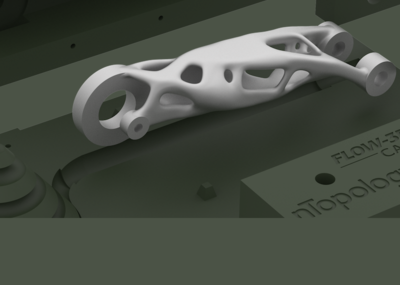

Based in Northern Italy, BEAMIT is an experienced 3D printing bureau, which offers to produce on-demand parts for clients using its suite of DMLS, SLS and EBM machines. The firm’s services address the needs of customers in the automotive, industrial, aerospace and energy sectors, and it has increasingly sought to qualify new materials for its printers as a means of expanding on their applications.

Back in 2019, the company signed a deal with SLM Solutions that has seen it install the SLM 280 2.0 and SLM 500 3D printers, and use them to qualify a variety of metal powders. During the project, BEAMIT has primarily focused on developing parameters for the nickel-based IN939 and IN718 alloys, which lend them unique properties and high-performance characteristics.

Likewise, the company has previously partnered with material developer BERCELLA to devise a joint method of 3D printing enhanced carbon fiber-reinforced polymers. By combining their technologies and expertise, the firms aim to create structurally-optimized parts, that are better-suited to aviation, space and defense applications.

Fast forward to May 2021, and BEAMIT also announced that it had developed a method of processing titanium Ti6242, which could prove capable of yielding eco-friendly aerospace and motorsport components, and it now appears to have made another LPBF advance, qualifying aluminum 2024 to address similar use cases.

“Our priority is to offer customers advanced materials and processes so they can transfer these innovations directly and effortlessly to their products,” said BEAMIT Group President, Mauro Antolotti. “This continually evolving advancement is an integral part of our Group’s long-term strategies and supported by a strong, well-organised team focused on achieving even more competitive results.”

Qualifying aluminum 2024

When processed using conventional technologies, ‘2000 series’ aluminums have often been used to create structural aircraft parts, but their composition has also made them difficult to 3D print with. This is because elements within alloys such as copper, zinc and magnesium solidify at varying temperatures, meaning that the lasers of each machine used to print them need to be configured accordingly.

To overcome this and develop a parameter set for 3D printing aluminum 2024, an alloy that’s attracting strong interest within the automotive sector, BEAMIT opted to partner with material developer Elementum 3D, which in turn, modified the metal using its patented Reactive AM (RAM) technology to lend it greater printability, before helping identify its optimal processing window.

By taking advantage of BEAMIT’s integrated value chain, and a multidisciplinary approach, the firms were ultimately able to develop a custom heat cycle to maximize the alloy’s mechanical performance. As well as optimizing the metal’s thermal qualities, the team also developed new post-printing processes for it, including in-air and HIP-Q treatments that enable it to be customized as needed.

“It is very difficult to process 2000 series aluminium alloys via L-PBF so developing this material really motivated us,” explained Alessandro Rizzi, Material and Special Processes Manager at BEAMIT. “The role of heat treatments became fundamentally important for Al2024 RAM2C, and enabled us to experiment with different ones to find repeatable, stable processes.”

Advances in 3D printed aluminum

Despite being ultra-lightweight, aluminums tends to soften over time and lose their rigidity when exposed to temperatures over 160°C, often leading manufacturers to opt for titanium or steel instead. However, over the last two years, aluminums have now been developed that seem to buck this trend, and exhibit higher levels of thermal stability and tensile strength.

Just last year, metal 3D printing specialist Amaero revealed that its high-performance aluminum alloy, Amaero HOT Al, had entered the final stage of patent approval. The unique metal formulation features high scandium content, meaning that it can be heat treated to boost its durability, and endure prolonged exposure at temperatures of up to 260°C.

Similarly, QuesTek Innovations has collaborated with the German Aerospace Center (DLR) to formulate a novel 3D printable alloy that exhibits high strength at elevated temperatures of between 200 and 300°C. The upgraded material is designed to replace titanium within certain applications, making components and equipment lighter than before.

In more experimental research, alloy providers such as Aluminium Materials Technologies (AMT) are still attempting to develop a parameter set for 3D printing A20X aluminum. Working with the University of Birmingham, the firm aims to identify the impact of compositional changes and treatments to the alloy’s properties.

Source: www.3dprintingindustry.com