Magnesium is one of the lightest metallic construction materials, easily recyclable and highly attractive for many industrial applications. Nevertheless, the material has so far remained a niche product, mainly because it can only be formed to a limited extent. Conventional processes quickly reach their limits, especially in the manufacture of wires.

This is where an international research project comes in: The aim is to gain a better understanding of the material behaviour of the calcium-containing magnesium alloy ZAX210 along the entire process chain, thereby enabling new, more efficient processing methods. The LKR Light Metal Competence Centre Ranshofen at the AIT Austrian Institute of Technology is using simulation-based methods to analyse how microstructure and texture develop from casting to wire drawing.

Formability as a key challenge

Magnesium is one of the lightest structural metals and can make a significant contribution to reducing emissions and increasing energy efficiency in mobility and industry. However, its industrial use is still limited by its limited formability, which is due to its hexagonal crystal lattice. Particularly in complex forming processes and multi-stage process chains, the interaction of temperature, forming speed, stress state and texture development has a negative effect on process stability and component properties.

In recent years, significant improvements have been achieved through new alloy concepts. In particular, the use of calcium as an alloying element has had positive effects on forming behaviour and texture development. The Mg-Zn-Al-Ca alloy ZAX210 is characterised by improved formability compared to conventional magnesium alloys, which is due to the targeted influencing of microstructure and recrystallisation. Nevertheless, a holistic understanding of the material behaviour of these alloys under real, industrially relevant process conditions is still lacking.

New process chain for the ZAX210 alloy

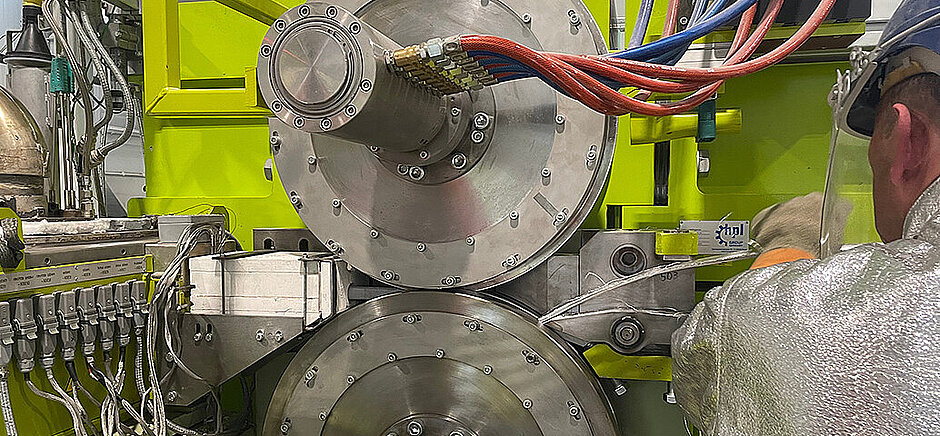

The project ‘Material behaviour along the process chain of ZAX210 wire’ is the first to systematically investigate the manufacture of magnesium wire products from the Mg-Zn-Al-Ca alloy ZAX210. The focus is on a novel process chain that combines twin-roll casting (TRC), continuous rotary extrusion (CRE) and downstream wire drawing. TRC combines casting and hot forming in a single step and enables the production of a homogeneous starting material with an improved microstructure. CRE is a resource-efficient, continuous forming process whose influence on microstructure and texture has not yet been sufficiently researched.

The aim is to achieve improved formability combined with high mechanical performance through the targeted promotion of dynamic recrystallisation and controlled texture development. This opens up new application prospects for magnesium wire, including in medical technology and wire-based additive manufacturing.

Contribution of the LKR: Simulation along the entire process chain

The LKR Light Metal Competence Centre in Ranshofen is contributing its many years of expertise in forming, microstructure and texture simulation to the project. At the macroscopic level, the individual forming steps along the process chain are simulated using adapted extrusion and forming models in order to systematically analyse the influence of key process parameters.

In addition, the LKR is investigating microstructure development – including grain morphology, phase proportions, texture changes and recrystallisation – along selected flow lines. The Visco-Plastic Self-Consistent approach, an efficient polycrystal approach for describing anisotropic material mechanisms, is used. This allows key phenomena such as dynamic recrystallisation and twin-induced recrystallisation to be realistically represented. The combination of macroscopic process simulation and microscopic material modelling enables a holistic understanding of the interactions between process control, microstructure and resulting material properties.

‘With this project, we are gaining an in-depth understanding of how process control, microstructure and texture interact in magnesium. These findings are crucial for the future economic and reliable use of magnesium alloys such as ZAX210 in demanding applications,’ emphasises simulation expert Johannes Kronsteiner, project manager at LKR.

Consortium and funding

The project partner is the Institute for Metal Forming (IMF) at TU Bergakademie Freiberg, which is contributing its proven expertise in experimental process development and twin-roll casting and is responsible for the overall coordination of the project.

The project is funded by FWF WEAVE, with a main submission to the German Research Foundation (DFG) and co-financing from the Austrian Research Promotion Agency (FFG).

LKR Light Metal Competence Centre Ranshofen

As a subsidiary of AIT, LKR Light Metal Competence Centre Ranshofen GmbH belongs to the AIT Centre for Transport Technologies as the ‘Light Metals Technologies Ranshofen’ competence unit. The LKR team of around 60 people is a leader in the development of high-quality light metal alloys, sustainable processing methods and functionally integrated lightweight components.

On the one hand, this requires the development of sustainable, efficient manufacturing processes for materials in order to drastically reduce energy consumption during production. On the other hand, the materials must meet the requirements for use in highly stressed components, e.g. in new electric mobility.

Aluminium and magnesium are also valuable recycling materials and offer an attractive incentive for economic recycling. That is why the research focus is on these two light metals in order to develop efficient, safe and environmentally friendly mobility solutions.