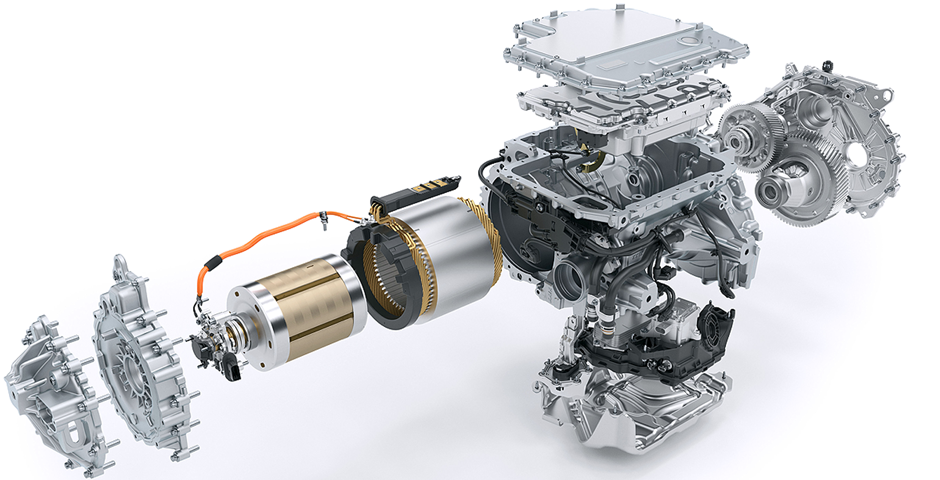

The partnership was set up to develop core making equipment dedicated to the production of the sophisticated BMW e-motor housings. The design of these housings (5 different versions) integrates the gearbox as well as the power electronics unit, making massive inorganic cores essential for production.

Inorganic Core Manufacturing Lines for high volume production of massive cores for BMW e-motor housing

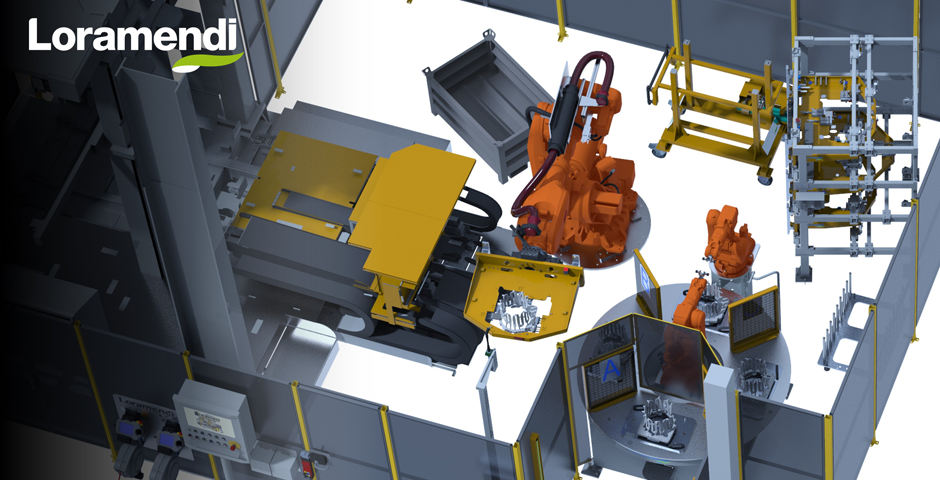

In 2020 the premium German automaker asked Loramendi to develop a core making installation to fill the existing gap for massive inorganic core production facilities for their e-housing. The project had a very demanding lead time and high output targets that could not be met with the customer's existing machines. The new core making line includes a sand plant and a fully automated 100L machine to produce the massive inorganic cores (up to 70 kg per shot).

After having successfully achieved the output rates and lead times of the first joint project for these housings, BMW decided to invest in a new core shop dedicated entirely to producing the e-motor housings: this new installation consists of a sand plant, one 100L core making machine (to produce the previously mentioned massive cores) and one 25L core making machine to produce the technically demanding water-jacket cores for this e-motor housing. During the development of the equipment, BMW and Loramendi again cooperated closely from the very from the very beginning of the project, as production rates had to be further increased for this new core manufacturing plant. As a result of this outstanding cooperation, it was possible to achieve the necessary key performance indicators, which has further cemented the long-standing relationship between BMW Landshut and Loramendi.

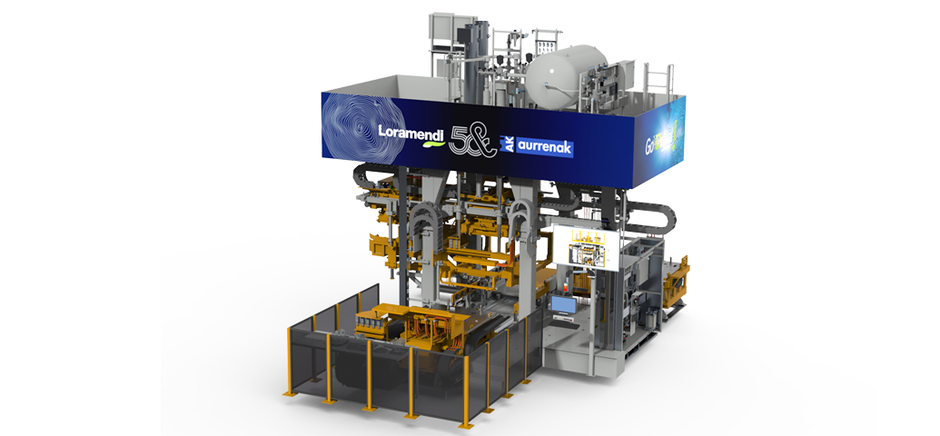

Based on this mutual trust and cooperation, Loramendi is now working on three additional core shooting machines for BMW, which include three sand plants, three 100L core shooting machines, and one 25L core shooting machine. One of these 100L machines will be shown at Loramendi’s stand at GIFA 2023 in Düsseldorf. If you are interested in learning more about our core shooting technology and this amazing success story, do not hesitate to visit us during GIFA 2023 at the Loramendi & Aurrenak stand E26 – E34 in hall 16. Our on-site technicians will be happy to answer any questions you might have related to this project. For interview requests, comments or suggestions relating to core shooting technology, please contact: info(at)loramendi.com