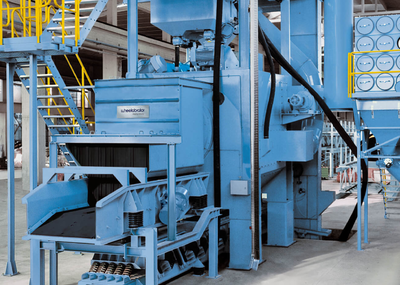

Wheelabrator has launched ATLAS Command, a blast wheel wear parts system that reduces shot blast running costs from the inside – without any upgrades to wheels or machine.

Designed to simply drop into existing ATLAS (formerly Universal/”U”) blast wheels, the ATLAS Command system tackles one of the biggest cost drivers of foundry shot blast processes: abrasive consumption.

The ATLAS Command system is initially available for the popular ATLAS 70x500 (U70x500) wheel (foundry version).

Christian Timmer, Head of Testing at the Technology Center Wheel at Wheelabrator, explains: “Foundry blast wheels throw hundreds of kilograms of abrasive per minute at castings - with the wear and energy use to match. Annual running costs are huge. And while parts and maintenance costs are perhaps the most visible, abrasive consumption (next to energy use) represents one of the two major chunks of blast wheel running costs. Bringing it down delivers serious savings. With ATLAS Command, foundries can now dramatically cut abrasive consumption through a simple wear parts change.”

Abrasive consumption down by up to 40%

ATLAS Command wear parts work together to reduce abrasive breakdown and to focus more energy on blasting, less on wear. Blades, impeller and control cage feature new designs that have been optimized as a system in rigorous testing. The result: reductions in abrasive consumption of at least 20% and up to 40% (for a typical foundry blast process with round steel shot).

Thanks to a new manufacturing process for the blades, the wear parts in the ATLAS Command system come with extended, synchronized operating lives. That means they can be changed less frequently and all at the same time, streamlining maintenance and reducing the number of parts purchases per year. Together with the reduced abrasive costs, this results in a combined saving of 15-35% on parts and abrasive alone.

Real results, in real foundries

The ATLAS Command system has been proven not just in the test center, but in real foundry environments at pilot customers.

At a foundry in Germany, ATLAS Command systems were deployed on a CT (Continuous Tumblast) machine with four 37kW ATLAS 70 blast wheels. Abrasive consumption fell by 20% (representing an annual saving of nearly €70,000).

On another CT, at a Spanish foundry, four 55kW ATLAS 70 blast wheels were switched to ATLAS Command parts, reducing annual abrasive consumption by 14.5 tons per blast wheel, in sum a cost saving of approximately €80,000 just on abrasive.

Running costs under the microscope

The ATLAS Command system is part of a strategic effort at Wheelabrator to deliver lower running costs through wear parts innovation. Wheelabrator’s Technology Center in Metelen, Germany, has recently invested in extra laboratory and testing capabilities to bring new wear parts for its wheel portfolio to market faster.

Magdalene Höltke, Senior Vice President Global Wheel at Wheelabrator, explains: “Especially in foundries, running costs and the efficient use of resources are under the microscope. While new machines or equipment upgrades are certain to deliver step changes in cost performance, they require capital investments and usually mean disruption to operations.

“That’s why taking a “total cost of ownership” view of wheel blasting and then lowering costs from the inside, with every wear parts change, is such a smart move. Alongside digital monitoring, deploying wear parts that tackle your main cost drivers is the fastest, most immediate way of slashing the total cost of your blast process.”

ATLAS Command is initially available for ATLAS 70/U70x500 foundry blast wheels. The system is offered as a wear-life-synchronized kit comprising the core hot parts, which are all exchanged at the same time, minimizing disruption. The kit is available in clockwise and counterclockwise versions.

The thinking behind ATLAS Command is already being applied to wear parts across other wheels in the Wheelabrator portfolio, alongside parts that extend maintenance intervals and reduce energy use.

More information on ATLAS Command can be found here.