The International Magnesium Conference, held on 4–5 December 2025 as part of the GDCTECH Forum in Pune, brought together international magnesium associations, global technology providers, researchers, equipment manufacturers, and representatives of Indian industry. The objective of the conference was to examine the evolving role of magnesium and its alloys in modern engineering applications from a holistic perspective. Topics ranged from geopolitical supply considerations and process and product technologies to application development, sustainability, safety, and challenges related to commercialization.

As the lightest structural metal, magnesium occupies a unique position in global lightweighting strategies. Regulatory pressure to reduce emissions, the electrification of mobility, and increasing demand for high-performance yet sustainable materials have further amplified its relevance. Accordingly, the conference addressed not only metallurgical and processing aspects but also the broader industrial ecosystem required for large-scale adoption.

Geopolitical and Supply Chain Perspectives

Several presentations highlighted the strategic importance of magnesium resources and supply chains. While magnesium is abundant globally, primary production is geographically concentrated. Analyses of global resource distribution and industrial policy demonstrated that China currently dominates magnesium production and processing, making magnesium a strategically sensitive material for the automotive, aerospace, and energy sectors.

For India and other emerging manufacturing regions, this concentration has two key implications. First, supply security and price volatility remain significant risks for downstream users. Second, there is a strong rationale for developing regional capabilities in recycling, secondary magnesium processing, and value-added manufacturing. In particular, the recycling of magnesium chips and machining swarf was positioned as a critical lever to reduce dependence on primary magnesium and to close material loops in lightweight manufacturing.

Processing Technologies – HPDC as the Dominant Method

High-pressure die casting (HPDC) clearly emerged as the dominant industrial processing route for magnesium. Comparative analyses of hot-chamber and cold-chamber die-casting systems illustrated fundamental differences in melt handling, air entrapment, cycle time, and defect susceptibility. Hot-chamber systems offer advantages in terms of shorter cycle times and reduced air inclusion, while cold-chamber systems provide greater flexibility for larger components and higher locking forces.

The concept of “Design for Magnesium” was repeatedly emphasized. Case studies on converting aluminum components to magnesium made it clear that magnesium cannot be treated as a simple drop-in replacement. Differences in density, viscosity, solidification behavior, and thermal properties require redesigned gating systems, runners, venting, and cooling layouts. Casting simulation was highlighted as an essential tool, enabling prediction of flow behavior, shrinkage, and porosity prior to physical trials.

Porosity Control and Quality Assurance

Porosity remains one of the most critical quality challenges in magnesium castings. Detailed discussions on vacuum pressure impregnation (VPI) demonstrated how impregnation has evolved from a remedial measure into a standard quality assurance process for safety-critical and pressure-tight components. The process sequence—vacuum evacuation, sealing, pressurization, cleaning, and polymerization—was shown to be effective in sealing both micro- and macroporosity without affecting dimensional accuracy or functional performance. The increasing specification of impregnation by OEMs reflects the growing maturity of magnesium applications in powertrain, transmission housings, and structural components.

Surface Engineering and Corrosion Protection

The high chemical reactivity of magnesium continues to limit its use in aggressive environments. Presentations on surface treatment technologies, particularly chromate-free conversion coatings, directly addressed this challenge. Modern systems based on zirconium, titanium, and other environmentally compatible chemistries were presented as effective alternatives to traditional hexavalent chromium processes.

These surface treatments serve a dual purpose: they provide intrinsic corrosion protection and act as adhesion-promoting layers for subsequent organic coatings such as e-coat and powder coating. Anodizing processes were also discussed as electrochemical methods for enhancing wear and corrosion resistance. The consensus was clear: corrosion protection must be treated as an integral part of component and process design rather than as a downstream corrective step.

Safety and Fire Risk Management

Safety in magnesium processing received significant attention, particularly with regard to Class D metal fires. Magnesium fires burn at extremely high temperatures and cannot be extinguished using conventional water-based or ABC fire suppression systems. Presentations on advanced dry extinguishing agents demonstrated how tailored salt-based formulations can form stable, oxygen-impermeable crusts over burning magnesium. The development of controlled-dispersion extinguishing systems and automated fire suppression solutions was identified as a critical enabler for broader magnesium adoption, especially in chip handling, recycling, and machining operations. Safety infrastructure was clearly defined as a prerequisite—not an optional add-on—for commercial magnesium processing.

Application Development and Emerging Opportunities

Automotive and Mobility

Weight reduction remains the primary driver for magnesium adoption in the automotive industry. Case studies on substituting aluminum components with magnesium demonstrated weight savings of 25–40% while maintaining functional performance. Applications such as engine covers, transmission housings, seat structures, cross members, and enclosures were discussed in detail. Faster solidification, improved vibration damping, and reduced machining effort were identified as additional benefits beyond weight reduction.

Medical and Precision Applications

Beyond automotive applications, new opportunities in the biomedical sector were presented. High-precision magnesium microtubes and biodegradable magnesium implants illustrated how controlled corrosion—traditionally a limitation—can be transformed into a functional advantage. Applications such as resorbable screws, plates, and stents highlight the breadth of magnesium technology when supported by precise processing and surface control.

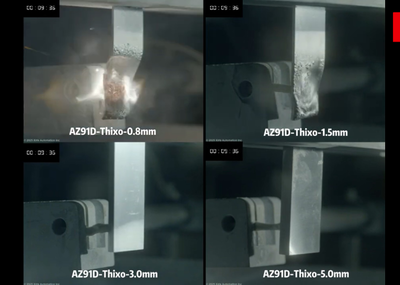

Die Casting and Alternative Processes

In addition to conventional die casting, thixomolding and other semi-solid processing technologies were presented as complementary manufacturing routes for thin-walled, high-precision components. These processes offer improved dimensional stability and reduced oxidation risk, expanding design possibilities for magnesium components in electronics and consumer applications.

Sustainability and Circular Economy

Sustainability was a recurring theme across multiple sessions. Magnesium’s low density directly contributes to reduced fuel consumption and emissions during the use phase of products. However, the conference emphasized that true sustainability requires a full life-cycle perspective—from raw material sourcing to end-of-life recycling. The recycling of magnesium chips, swarf, and scrap was presented both as a technical challenge and a commercial opportunity. Controlled recycling processes can convert machining waste into high-quality secondary raw materials, significantly reducing CO₂ footprint and material losses.

Commercialization Challenges

Despite its technical maturity, magnesium technology still faces barriers to wider commercialization. These include supply chain concentration and price volatility of primary magnesium, perceived risks related to fire safety and corrosion, limited domestic experience with magnesium-specific design and tooling, and the need for specialized infrastructure for melting, handling, and recycling. The conference clearly demonstrated that these challenges can be addressed through technology deployment, training, and ecosystem development. Close collaboration between material suppliers, equipment manufacturers, surface treatment specialists, and end users is essential to mitigate adoption risks.

Concluding Remarks

The International Magnesium Conference at GDCTECH Pune successfully positioned magnesium not merely as an alternative material, but as a strategic enabler for lightweight, sustainable, and high-performance engineering solutions. The discussions reaffirmed that magnesium technologies have reached a level of technical maturity suitable for large-scale industrial deployment, provided they are supported by appropriate design methodologies, safety frameworks, and surface engineering solutions.

From the perspective of the Indian manufacturing industry, the conference outcomes are particularly significant. India’s strong automotive base, expanding foundry and die-casting capacities, and increasing emphasis on sustainability create a favorable environment for accelerated magnesium adoption. The presence of global technology providers, Indian system integrators, and end-user industries on a shared platform enabled meaningful dialogue across the entire value chain.

This event marked the second successful conference on magnesium casting technology jointly organized by the GDCTECH Forum and the International Magnesium Association. With strong support from the IMA, six international technical presentations and four international exhibitors were featured. Participation extended beyond the magnesium industry to include representatives from aerospace, automotive, and hand-tool sectors, signaling a clear trend toward growing industrial adoption of magnesium technologies.

Source: www.intlmag.org