Today’ strict emission standards govern not only car emissions, they apply to fuel vapors, too. In most cases, these vapors are trapped in an activated carbon canister mounted close to the fuel tank. This canister needs to be regularly purged. For this purpose, Pierburg GmbH has now developed a compact innovative pump that works even without the intake pipe vacuum necessary until now. The electric pump is the first of its kind and will go into a customer’s series production in 2018.

Among the factors governed by fuel vaporization legislation is the amount of volatile hydrocarbon compounds that may exit a vehicle’s fuel system. Inside the canister, the activated carbon collects the fuel vapors, binding them until they are burned in the engine. The canister’s capacity for storing these compounds is, however, limited and hence fresh air must be regularly injected in order to avoid saturation. Under all engine operating conditions in which the additional volume of fuel vapors is tolerable for the engine and the combustion process, a valve therefore opens to allow the vapors to escape into the intake manifold or flow in the direction of the turbocharger.

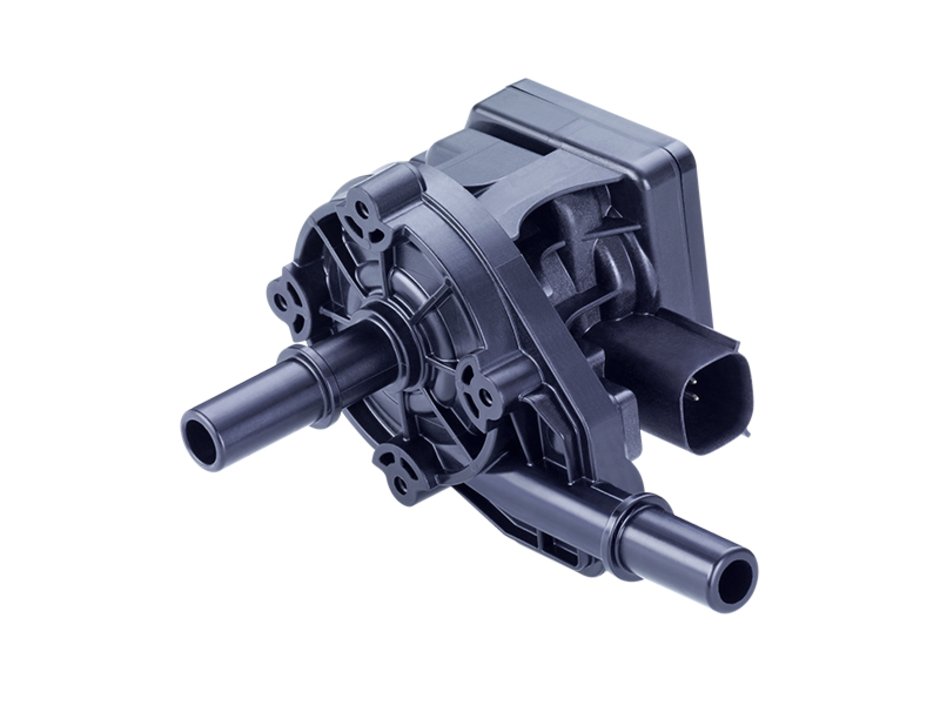

In the past, the vacuum arising when fresh air was drawn into the engine was sufficient to draw the fuel vapors into the engine and, at the same time, allow fresh air to flow into the activated carbon canister. Today’s engine generations without a sufficient supply of vacuum require, however, some kind of solution that actively helps clean the canister. For this purpose, Pierburg's new electric vacuum pump offers an attractive, customer-friendly solution that, at the same time, takes account of the increased significance of onboard diagnosis while checking for any leakages.

Light weight and rapid response

Pierburg has many years of experience in electric coolant pumps and, drawing on this expertise, has developed the vapor pump as the centrifugal electric model of a gas pump. The pump is driven by a monophase motor adapted to the high throughput and low pressure required by the application. The torque level ensures quick start-up and response of the pump, while the centrifugal design allows it to work with low energy consumption even against the closed valve.

Weight and costs are low thanks to the many plastic components. Innovative active cooling of the electronics improves the pump’s thermal resistance. This cooling also ensures that the new pump withstands the arduous conditions within the engine compartment. An integrated sensor reports system pressure to the monitoring unit.

Source: Rheinmetall

Partner

Foundry Daily News

Market innovation: new fuel vapor pump

Reading time: min

[0]