Masc Global Industries (MGI Group) continues to strengthen its position in the global market for non-ferrous and ferrous casting crucibles through measured capacity expansion, operational discipline and a long-term focus on export partnerships and application reliability.

Capacity expansion ahead of demand growth to support reliability

Over the past 18 months, MGI has expanded its installed production capacity from 300 tonnes to 600 tonnes per month through targeted investments in new equipment and process improvements. This expansion was carried out ahead of the surge in demand, enabling the company to improve production stability, reduce bottlenecks and ensure consistent quality across a broader range of products.

To further strengthen scalability and consistency between batches, MGI plans to expand by an additional 200 tonnes per month in the next phase. This includes the installation of a second automated mixing plant and a second cold isostatic press (CIP), which will enhance redundancy, risk mitigation and long-term capacity assurance for global customers.

Sustainable revenue growth through customer loyalty

In addition to this operational expansion, MGI has also made steady commercial progress. Monthly sales volume increased from approximately 200 MT to 300 MT, representing 50% growth, primarily driven by repeat orders and long-term customer loyalty rather than short-term volume increases.

This approach reflects MGI's strategy of prioritising application suitability, pot life and reliability over aggressive capacity utilisation to ensure sustainable growth rather than cyclical fluctuations.

Shorter lead times through proactive inventory planning

MGI has significantly reduced average delivery times – from around 45 days to around 20 days – by strategically stocking standard crucible sizes based on historical consumption patterns.

Instead of reactive production planning, this inventory-oriented model enables customers to:

- Plan smelting operations with greater certainty

- Reduce furnace downtime

- Respond more quickly to fluctuations in metal demand

At the same time, inventory levels are continuously reviewed to ensure a balance between service levels and working capital discipline.

Application-oriented technology instead of one-size-fits-all products

MGI works closely with its customers to understand furnace designs, alloy chemistry, operating temperatures and melting processes. While maintaining a standardised core product platform, the company offers controlled customisations that deliver measurable performance benefits – especially in induction furnace applications.

This application-focused approach enables customers to achieve consistent value without compromising manufacturing repeatability.

Proven performance in high-stress melting environments

MGI crucibles are frequently used in demanding non-ferrous applications and excel in the melting of copper and copper alloys, where thermal shock, chemical attack and oxidation rates are significantly higher.

Demand in this segment continues to grow, driven by downstream industries such as electric vehicles and solar energy. MGI's ongoing research and development efforts focus on:

- Advanced coatings

- Optimisation of raw materials

- Process control for consistent service life

Quality systems with a focus on prevention and learning

Quality assurance remains at the heart of MGI's business. Automated dosing systems, defined process controls and a dedicated quality team support batch-to-batch repeatability on a large scale.

When deviations occur – as can be the case with any high-temperature consumable – MGI emphasises structured root cause analysis, application engineering support and customer training to ensure that problems are systematically resolved and the lessons learned are incorporated into process improvement.

Integrated access to raw materials for stability and consistency

MGI's involvement in the sourcing and processing of natural graphite flakes and powders ensures greater supply stability, shorter lead times and tighter control of raw material variability. This integration supports consistent product performance while improving resilience to global supply disruptions.

Export-oriented growth with long-term partnerships

Exports are a key pillar of MGI's growth strategy, which delivers through long-standing relationships with distribution partners in over 25 countries. Close collaboration with partners ensures:

- Consistent quality expectations

- Predictable deliveries

- Faster technical feedback from different markets

This relationship-oriented model supports gradual, sustainable expansion in different regions rather than opportunistic volume spikes.

Investment in employees and business continuity

This growth is supported by a continuous focus on training, safety and workforce stability. MGI invests in skills development and the assumption of responsibility for processes at the workshop level, as the company recognises that repeatable quality and delivery reliability ultimately depend on its employees.

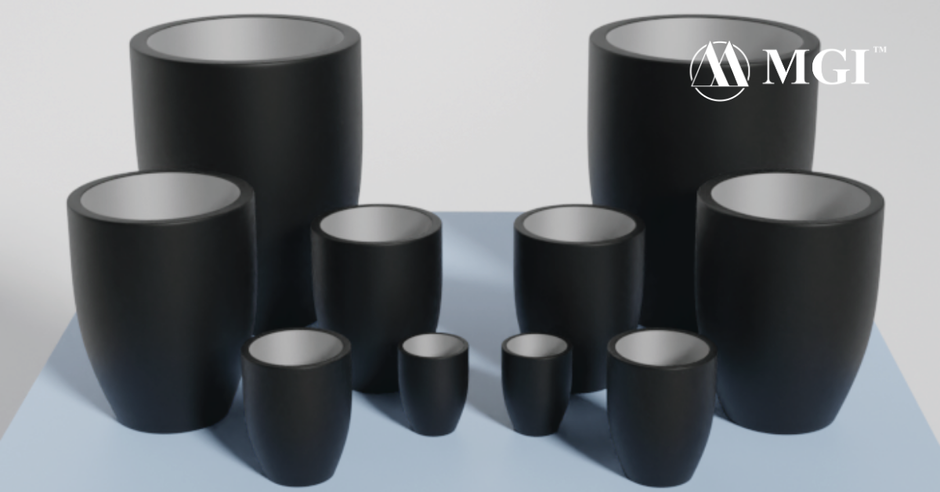

Masc Global Industries is a leading manufacturer and supplier of high-quality crucibles and crucible accessories. The company specialises in silicon carbide crucibles, isostatically pressed graphite crucibles and clay-graphite crucibles, and with over five years of industry experience, serves the needs of a wide range of industries. These include non-ferrous metal casting, precious metal refining, metal powder production, copper and brass casting, the electronics industry and alternative energy applications.

Masc Global Industries is characterised by its in-depth technical expertise and its ability to provide the optimal crucible for every application. The products are made from first-class materials and manufactured using state-of-the-art production technologies to ensure maximum performance and a long service life.

The company consistently pursues the goal of combining competitive prices with consistently high product quality. Through the continuous optimisation of business processes and resource utilisation, high quality standards are met on a sustainable basis.

Masc Global Industries has experienced strong growth in its first five years of operation. This growth is set to continue in the future through innovation, uncompromising quality and exceptional customer service.