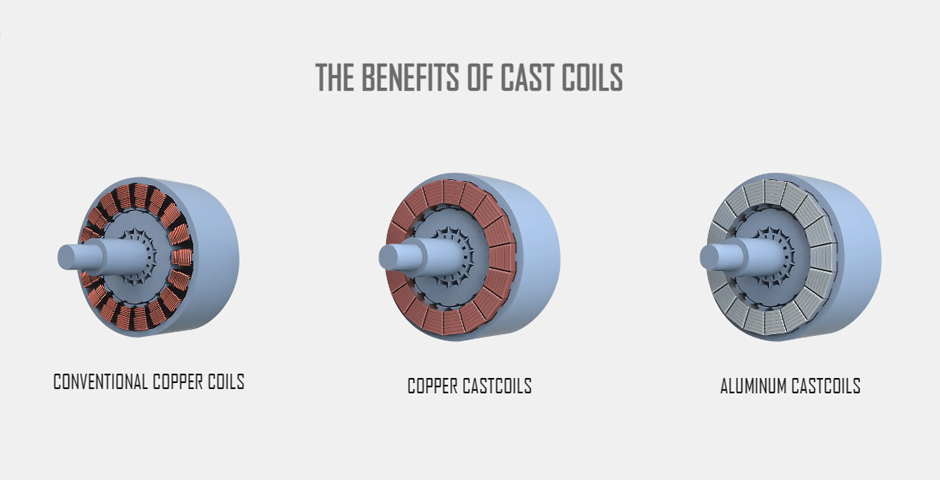

They can be used to replace combustion engines, which are still operated almost exclusively with fossil fuels. But electric motors have reached their limits with conventional technology. Significant efficiency gains have not been achieved in recent decades.

Conventionally, copper is used in the form of cables and coils in electric motors. However, with a share of 0.01% of the world's raw materials, copper is only available in a few mining areas. lf a rare commodity meets rising demand, this entails not only rising prices, but the risk, that monopolistic corporations will abuse their cornering position.

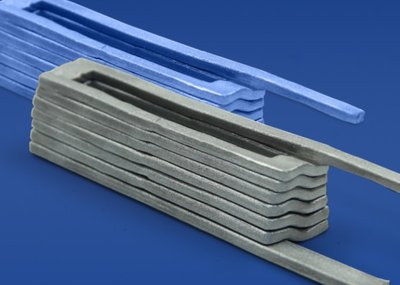

More than 10 years ago, a team from the Fraunhofer Institute IFAM in Bremen proved that there are alternatives: The cast coil {CASTCOIL) was developed and patented in recent years with a whole bundle of technological specifications and related processes. A few weeks ago, the research team set up its own business and secured the exclusive rights of use and marketing.

Franz-Josef Wöstmann, one of the inventors and managing directors of Cast Coil GmbH, explains this step:

"CASTCOIL is a groundbreaking development. The manufacturing process not only allows us to make use of new designs in engine construction, but also allows us to use new materials. In particular, aluminium is worth mentioning, which is highly interesting for e-mobility due to its low weight and it enables cooling appliances without CFCs."

New geometries, lower weight and a raw material that is the third most abundant element in the world at 8.1%- this allows for smaller motors, lower energy consumption and more resource-efficient production.

However, for Denise Ulbrich, CEO of the Bienenelfe Foundation, these are only partial aspects:

"We are convinced that CASTCOIL is a perfect fit to our vision of "change an a sma/1 scale to achieve great things''. Research and science have succeeded in overcoming a law of nature in the production of electric motors. Now it must be a matter of shaping the transformation and accelerating the reduction of greenhouse gases (especially C02 and CFCs) with the help of CASTCOIL."