With a goal of generating longer crucible service life and increased energy savings, Morgan Molten Metal Systems (MorganMMS) has introduced its Syncarb Z2 e², the latest member of the Syncarb Z2 family. Designed specifically for aluminum melting and holding applications, the Syncarb Z2 e2 (energy efficiency) has undergone extensive lab and field testing with powerful results confirming an operational performance that surpasses competitive “energy” crucibles in both reduced energy consumption and durability.

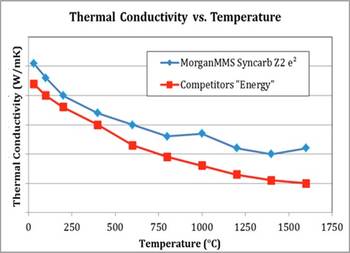

The entire Syncarb Z2 line is composed of iso-statically pressed, hybrid ceramic bonded crucibles with a high silicon carbide and graphite content. They display a higher breaking strength due to an improved granulation process resulting in an increased resistance to damage and higher stresses during operation and handling. The new Z2 e2 displays higher thermal conductivity at all working temperatures, translating to increased energy savings for customers.

“The MorganMMS Technology Team, with its development of the Syncarb Z2 e2, has created a crucible designed specifically for optimum energy savings and efficiency,” says Brandon Kruse, Global Product Manager, MorganMMS. “We at MMMS are genuinely excited about its future, which promises to have a positive impact on foundry performance and our customers’ bottom line.”

Measureable Benefits

The new Z2 e2 brings a number of material and structural advantages to help improve crucible performance and foundry operations. Over and above offering a 56% higher transverse breaking strength than the competitor’s “energy” crucible, the Z2 e2 maintains integrity at relatively higher values due primarily to the granulation of the mix, processing parameters and advanced materials.

In addition, through its advanced glaze technology, the Z2 e2 showed an average 10% increase in oxidation resistance over the competition in both five and ten day Loss On Ignition (LOI) tests.

MorganMMS has been able to develop a crucible that has been scientifically proven by an independent lab to achieve superior thermal conductivity over all working ranges (see below) while maintaining a standard wall thickness. This achievement directly correlates to increased energy efficiency and savings.

Furthermore, it is important to note that thermal conductivity will degrade over time as any crucible oxidizes, it has been confirmed that the oxidation process occurs slower in the MorganMMS Syncarb Z2 e2 crucibles. This reduced degradation, combined with a higher thermal conductivity, results in further energy savings over the competition, not only when the crucible is new, but throughout its lifetime. All this translates to longer run times, more heats, less energy usage and an overall melting solution advantage to MorganMMS customers.

Proven Product Line Performance

The Z2 e2 is the latest innovation to evolve from the MorganMMS line of Syncarb Z2 crucibles. The entire product line has already proven itself in numerous customer operations throughout the world and has led to significant cost savings through its survivability in harsh environments such as copper melting and refining. In fact:

Carl Bednark of MetalTek International: “We’ve experienced a very dramatic improvement in average crucible life with Z2 crucibles versus other products used in the past – two times the life in fact. We expect the Syncarb Z2 crucible to have a major impact on our operations.”

###COMPANY_LINK###<link linktosingle> Morgan Molten Metal Systems