The focus is on cost structure and localization, illustrated by the example of BMC Precision Machinery, where we were able to gain first-hand insight into the company’s technical capabilities.

At EUROGUSS in Nuremberg, Europe’s leading trade fair for die casting, Chinese machine manufacturers are no longer positioning themselves merely as low-cost alternatives. Instead, an increasing number are competing directly in the European high-performance segment by rethinking the relationship between machine performance, total cost of ownership, and local support structures.

A representative example is BMC Precision Machinery, which presented a clearly defined strategy based on the concept of performance equivalence combined with cost efficiency.

Machine platforms for high-stability structural die casting

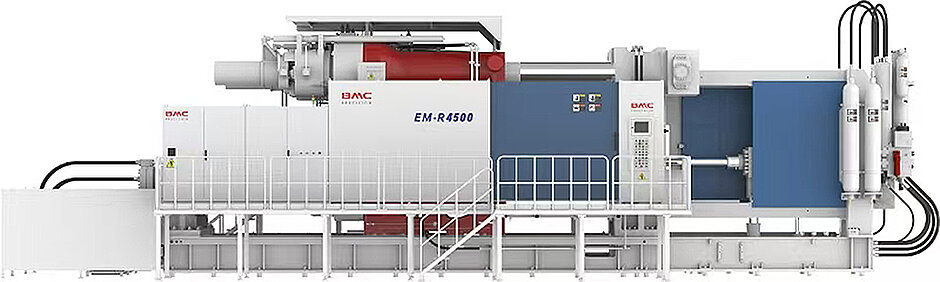

Rather than focusing solely on market visibility, BMC’s message at the show was explicitly geared toward Europe. The company presented its EM-R two-platen die casting machine and EM-K three-platen machine, covering clamping forces from 550 to 4,500 tons.

These platforms are positioned for applications where structural stability and process consistency are critical, such as integrated automotive structural components. The underlying objective is not disruptive performance beyond established European benchmarks, but the ability to achieve a comparable technical level with a more favorable cost structure across the entire machine lifecycle.

Machine safety, ease of use and intelligent process control

A key element of this positioning is the adaptation of the system to European operating environments. Beyond meeting CE requirements, the machine design emphasizes safety interlocks, comprehensive process monitoring, and operator-friendly ergonomics.

Intelligent control algorithms automatically stabilize process parameters, reducing dependence on highly specialized operators. This approach directly addresses the growing shortage of skilled labor faced by many European foundries.

Process stability, yield control and quality costs

From a process perspective, machine intelligence is positioned not as a digital add-on but as a tangible value driver. More precise control of injection parameters improves yield stability, reduces material waste, and ensures dimensional accuracy over extended production runs.

These effects are particularly relevant in high-volume automotive and structural applications, where even small deviations can accumulate into significant quality and cost risks.

Energy efficiency and resource savings in machine design

Sustainability forms the second pillar of the European strategy. Two-platen clamping structures are presented as a means of lowering energy consumption, while optimized lubrication concepts significantly reduce oil usage.

Compatibility with recycled aluminum alloys further aligns the machine design with European regulations and customer-driven sustainability goals. Resource efficiency is thus integrated into overall production economics rather than treated as a separate requirement.

Localization of service, spare parts and response times

Market access in Europe depends on more than machine specifications alone. Accordingly, BMC places strong emphasis on localizing after-sales support.

The establishment of a permanent service team and a spare parts warehouse in Poland, combined with defined response-time commitments, reflects the understanding that uptime and service reliability are critical for Tier-1 suppliers operating under tight delivery schedules.

From machine supplier to technical complement

Strategically, the primary target group consists of suppliers to European OEMs who are simultaneously under pressure in terms of quality, cost, and delivery performance.

The intended role goes beyond that of a traditional machine vendor. Instead, BMC aims to position itself as a technical complement capable of supporting cost optimization without compromising process stability. Beyond automotive applications, growth areas such as energy storage housings and construction machinery components have been identified, where high requirements for rigidity and stability favor this approach.

Conclusion

BMC’s presence at EUROGUSS points to a structural shift within the European die casting machinery landscape. Competition is increasingly determined not by price alone, but by the ability to combine established performance benchmarks with alternative cost and service models.

Whether this approach will enable new market entrants to evolve into long-term reference suppliers remains to be seen. What is clear, however, is that the definition of performance and value in the European high-end foundry market is changing.