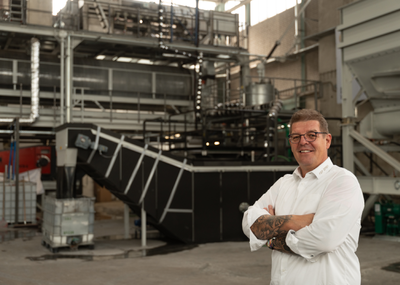

For generations, the family-owned company Quarzwerke has stood for quality and innovation. Today, this philosophy is reflected particularly in its consistent dedication to climate protection and resource efficiency. At its headquarters in Frechen and its site in Haltern, the company is advancing with ambitious energy projects – demonstrating that industrial production and ecological responsibility are not mutually exclusive. In our discussion with Maximilian Schratz, Markus Schramm, and Joachim John, it became evident how strategically and at the same time practically the company is pursuing its vision of climate-neutral raw material production.

The new PV system at the Frechen site pays off

Since the commissioning of the new photovoltaic system at the Frechen site, Quarzwerke has already saved nearly 3,000 tonnes of CO₂, making an important contribution to climate protection. Due to an unfortunate cable theft, the system had to be temporarily shut down – without this incident, around 700 additional tonnes of CO₂ would have been avoided. Currently, on average, about two-thirds of the generated electricity is used directly on-site, depending on solar radiation, production capacity, and process control. With the planned use of modern storage technologies, this self-consumption rate is expected to increase further. Overall, the use of renewable energies reduces the CO₂ footprint of the well-known F34 quartz sand by around 25%.

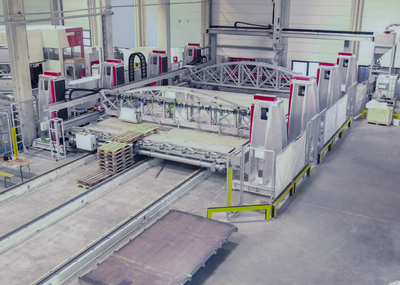

A look into the future shows: this is only the beginning. For the Haltern site, Quarzwerke is planning an expansion to a generation capacity of 40 MW – a key milestone on the path to the full decarbonization of one of Europe’s largest quartz sand plants. The concept goes far beyond traditional photovoltaics: it includes wind power, battery and heat storage solutions, as well as in-house production of green hydrogen for internal energy use.

Particular attention is deserved by the floating PV installation on the Silbersee III, which serves as a pilot project within the company’s climate neutrality concept. Floating systems do not require additional land and enable space-efficient energy generation on existing extraction lakes – an approach that is both technically and ecologically convincing.