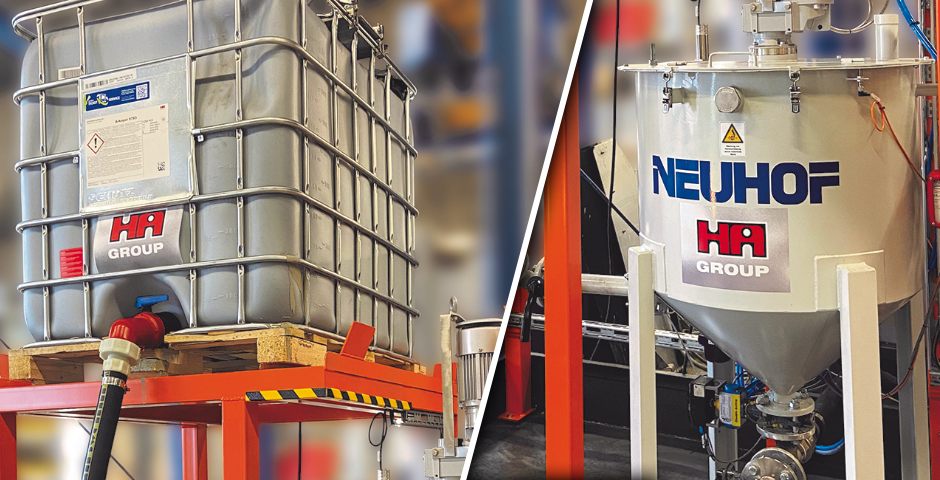

Together with our partner Neuhof Giesserei- und Fördertechnik, the HA product management team for refractory coatings set out to develop a pragmatic, space-saving and cost-effective solution. The CCU (Compact Coating Unit) resulting from this partnership has been adapted focussing on essential parts. For example, the use of diaphragm pumps was dispensed with and instead a solution was developed for using gravity to transport material from undiluted coatings to a ready-to-use form, set to the respective target densities.

The pre-determined density is set using pressure sensors and level measurement by laser technology. The system automatically feeds the undiluted coating with the corresponding carrier liquid for dilution. Homogenized and ready-to-use material is available at any time from a storage container designed to suit the respective quantities consumed. A pre-determined volume (manual or automatic) is delivered to the respective consumer (flooding system, dip tank, transport trolley, etc.) when a request signal is given. Communicating systems (between storage tank and consumer) were deliberately omitted in order to provide only "fresh material" when required. This prevents contamination of the coatings in the storage tank by foreign substances (e.g. core- / moulding sand residues, release agents, etc.).

This new developed preparation plant is available for both water and alcohol coatings and is also used in the Center of Competence of Hüttenes-Albertus Chemische Werke GmbH for the adjustment of coatings for the pre-series production of various automotive castings.

Contact

If you have any questions or are interested, the product management team for coatings and the contact persons at Neuhof Giesserei- und Fördertechnik will be happy to provide advice and assistance at any time

www.ha-group.com // pm.germany(at)ha-group.com | www.neuhof-gft.com // info(at)neuhof-gft.com