New developments in INOTEC™ technology

ASK Chemicals has succeeded in further enhancing its inorganic INOTEC™ technology through its new INOTEC™ TC 5000 and INOTEC™ HS 3000 products. The new developments lead in particular to improved shakeout and higher moisture stability of the cores.

The mounting advantages of using INOTEC™ technology for the foundry industry are not only odorless core production and odor-reduced casting, but also the significantly lower cleaning required for machines and tools, leading to productivity increases for foundries. Inorganic binder systems also offer casting advantages that result in stronger components.

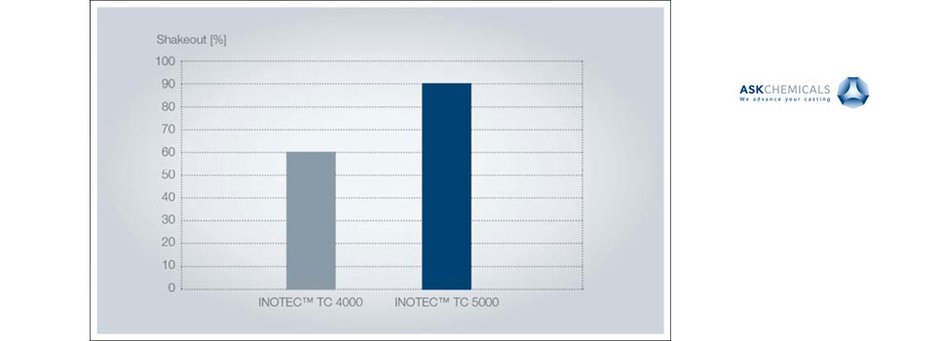

Improved shakeout and surface quality

The newly developed promoter INOTEC™ TC 5000 complements the positive qualities of the previous generation in regard to penetration-free and sand-adhesion-free casting surfaces, and in terms of improved collapsibility properties in light metal casting (Figure 1), improved immediate strength levels, as well as increased storage life of the cores. Previously, the decoring of cast parts manufactured with inorganic binders presented a challenge in relation to water jackets, especially if the gutting machine had limited degrees of freedom. INOTEC™ TC 5000 now enables even complex and delicate water jacket cores to be safely shaken out after casting. The system is 100 % inorganic and leaves no residual condensate deposits in the tooling, nor causes any smoke to form during the casting process.

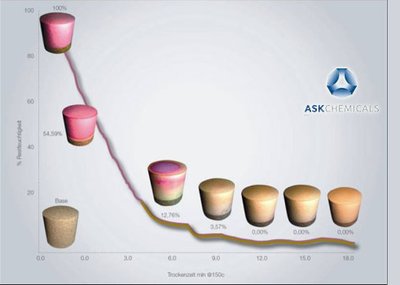

Enhanced storage life and moisture stability

Likewise, the storage life of cores manufactured using inorganic binders previously posed a challenge, especially on hot summer days with high humidity and a high ambient temperature. Now, the new binder INOTEC™ HS 3000 significantly improves the moisture stability of the inorganically bound cores (Figure 2). This in turn makes it possible to manufacture stable cores coated with a water-based coating, which also makes the INOTEC™ binder system interesting for iron casting.

ASK Chemicals will be presenting these and other solutions at the GIFA in Duesseldorf from June 16 – 20, 2015 in Hall 12, Stand A22.

Partner

Foundry Corporate News

Topic Chemicals

Topic Coremaking

Topic Sand & Binders

Remarkable casting advantages of the new INOTEC™ generation

Reading time: min

[1]