Rheinmetall has secured two important orders for back pressure valves for commercial vehicles. A well-known engine manufacturer from China has ordered intelligent electronically commutated back pressure valves for 12-litre diesel engines. Meanwhile, a South American customer has placed an order with the company for pulse width-modulated back pressure valves for 3.8- as well as 4.5- and 6.7-litre engines. Delivery of the parts earmarked for China will take place in the 2021-2025 timeframe. In keeping with the principle of “local for local”, the valves will be produced in China. Conversely, the components slated to go to South America will be manufactured at Rheinmetall’s plant in Ústi nad Labem in the Czech Republic, and shipped during the period 2022 to 2027. Together, the two orders are worth €37 million without value added tax. Both orders will be coordinated by Rheinmetall subsidiary Pierburg GmbH of Neuss, the Group’s specialist for emission-related, environmentally benign components.

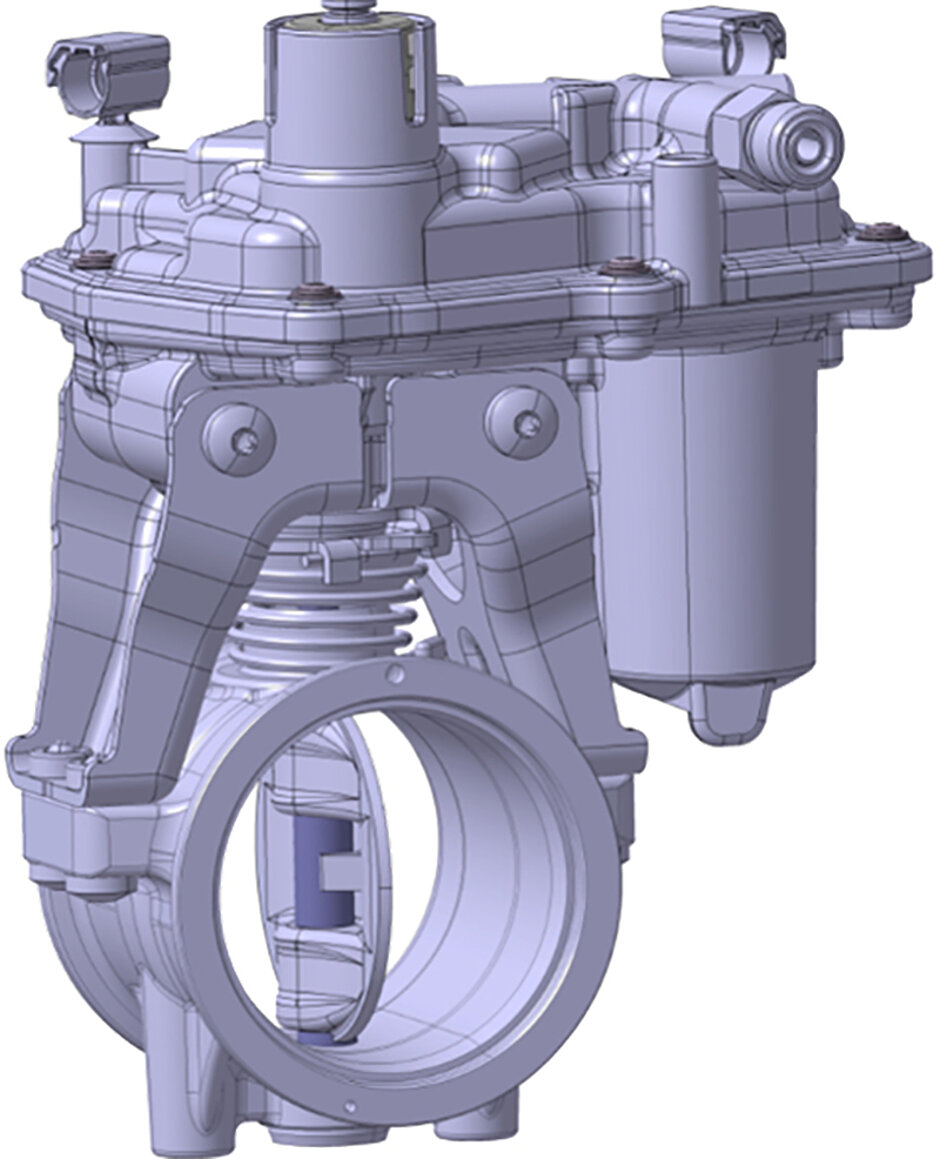

Back pressure valves help to reduce engine exhaust emissions and optimize fuel consumption. The valves are integrated into the engine control management via customer-specific interfaces, while flexible adaptation of the flange geometry makes it possible to instal the valves in different types of vehicles. Furthermore, electromotor concepts adapted for various durability requirements are available now as well. To sum up, this is a highly effective means of emission management.

As a leading systems maker, Rheinmetall is a single-source supplier of complete systems of valves and actuators. The versatile modular design of the back pressure valves makes them equally suitable for light-, medium-, and heavyweight vehicles. Moreover, the components for commercial vehicle engines are specially designed to withstand heavy vibration, temperature and pressure stress.

These orders are clear evidence of the trust engine-makers place in Rheinmetall’s expertise in the field of emissions and thermal systems. Furthermore, they make a durable contribution to the company’s commercial vehicles business, while strengthening its ties to globally operating engine manufacturers – even more so since Rheinmetall has maintained a strong relationship with the customers’ parent company ever since 2013. Further follow-up orders can therefore be expected.