also avaible in <link _top> <link _top>

<link _top> <link _top>

<link _top> <link _top>

<link _top>

Space S.r.l.

INVICTA GROUP of France choose “Space”

In spite of the worldwide industrial downturn, SPACE Srl, market leader for projects and manufacturers of green sand processing and preparation plant, have been successful in obtaining several orders in 2008 from many parts of the world. The most recent of those received is an important order from the French group INVICTA.

INVICTA is a manufacturing company, leaders in the field of wood burning stoves, hearths, grates, cast iron pans and ornamental furniture, with its own foundry, located in the French Ardennes. Their components require not only a good metallurgical quality but also a faultless surface finish, obtained only from a moulding sand, having perfect characteristics.

When INVICTA had to choose a partner to commit for the supply of two green sand processing and cooling plants, the decision was made in favour of SPACE, because of their specific know-how. INVICTA had also liaised with other Space clients, thanks to the numerous important positive references Space have for similar installations.

|

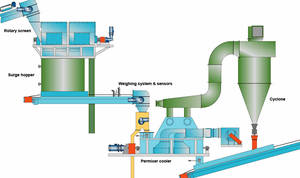

The content of the contract consisted in the supply of two installations, destined to feed the DISAMATIC moulding lines. The aim was to produce well stabilized return sand with constant moisture and temperature as well as the reintroduction and pre-mixing of a percentage of the filter fines as well as a proportion of fresh bentonite.

It is a well known fact that return sand contains a percentage of unburnt bentonite (live clay) that can be reactivated by adding water. The best way to obtain this reactivation is to store the sand for at least one hour in the storage silos, having first suitably treated it by adding water relative to its temperature. (ideally, 36 - 38 °C and 2 - 2.2% moisture.) During this time the bentonite slowly absorbs the water allowing it to develop in a natural way. At final mixing, it is now only necessary to add ‘trim water’ and the reduced dry additions, as required, to reach the exact characteristics for good moulding. The sand obtained in such a way has much better flowability, better mouldability, no free water and is the perfect media for the manufacture of sound castings with a superior surface finish.

Space PGF-3-CP equipment, completely designed and developed by SPACE, and foundry proven over the years, world wide, maintains the narrow moisture and temperature values required. The system manages the water, air dosing to MUR Premixer Cooler and additions control according to the required specification, so as to achieve the optimum results.

In spite of the general situation of the world economy, SPACE continues its own expansion and its many successes testify to the quality and the reliability of its products.

NOTE: The first Invicta installation has been in production since the start-up in November 2009, with complete customer satisfaction.

<link _top>Click here for more Information and Contact to Space S.r.l. in our Suppliers Profile