Scania aim to have a melted capacity of 90,000 Tons per annum for predominately their cylinder head and block castings used in their global truck and bus vehicles.

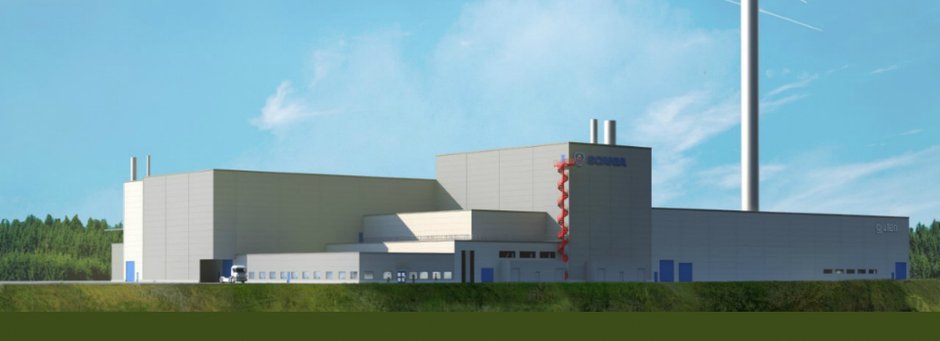

The facility will be at the cutting edge for technology, efficiency, sustainability and with a minimal environmental footprint.

The new foundry, at full capacity, will triple its current foundry production whilst using the same labour and only 50% of the energy consumption. It will be run using 100% renewable energy and heat from the moulding area will be re-used throughout the facility.

Sustainability is also a major consideration and with a finite resource like sand. The ability to re-use is a strong position to future-proof Scania, as new sand and waste removal costs continue to increase.

The Sand Reclamation at the heart of the Scania System will be supplied by Omega Sinto Foundry Machinery in the UK, who have secured a multi-million pound contract after a rigorous selection process. The Omega Sinto secondary attrition equipment will be able to process 16 tons of waste sand per hour and convey it quickly and easily to Scania’s cold box core facility for re-use.