Already a leading-edge foundry with low scrap rates, Condals deployed the Monitizer IIoT platform at its two facilities in Manresa, Spain and Štúrovo, Slovakia. It collected data and built its own dashboards to monitor live process KPIs using Monitizer | DISCOVER, then applied AI to optimize casting quality through Monitizer | PRESCRIBE. It also implemented the Monitizer | DETECT predictive maintenance system to keep its DISA equipment working perfectly.

“Monitizer | DISCOVER, PRESCRIBE and DETECT help us reduce scrap and increase efficiency, both of which improve sustainability,” says David de la Cruz, Chief Digital Officer at Condals. “With these investments and our commitment to constant improvement, we have already achieved a 54.1% reduction in our overall scrap rate for AI-optimized, compliant castings.”

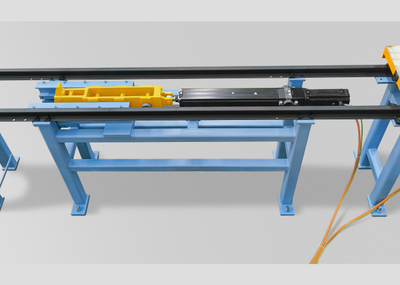

Next-gen foundries: Increasing automation and process visibility

Condals produces over 40,000 tons of iron castings each year for the automotive, railway and construction sectors. In 2018, it decided to transform its sophisticated plants into next-generation digital foundries with the Monitizer suite.

Leveraging Monitizer’s unique mix of digital and industry experience, this modular IIoT platform uses real-time data, AI and expert-driven insights to transform foundry performance across scrap rates, energy consumption and sustainability. Condals started its digital journey with Monitizer | DISCOVER to enable data collection and intelligent automation.

DISCOVER collects data from any vendor’s equipment across multiple lines or facilities in any location, presents it for real-time monitoring in intuitive dashboards, and stores it in a single, central database for analysis.

The winning formula: AI prescriptions plus expert governance

“DISCOVER gives us a complete picture of what’s happening in real time,” says Anna Castells, Chief Quality Officer at Condals. “That visibility helps everyone, from operators to managers, make better and faster decisions.”

Condals then put Monitizer | PRESCRIBE’s automated AI-driven analytics to work on the data collected by DISCOVER. PRESCRIBE optimizes an entire line, recommending optimal process parameters – “prescriptions” – that maintain stable, high-quality production to significantly reduce scrap and improve profitability.

Initial testing delivered an average 42% scrap reduction on two test patterns. When Condals put PRESCRIBE into production at Manresa, it quickly realized that successful optimization required strong change management and governance, not just technology.

It identified the key success factors as 1. coverage: how many patterns have enough data for effective modelling; and, more importantly, 2. compliance: how precisely operators follow the AI-generated control plan on their machines.

Empower your people to raise AI effectiveness

To increase compliance, Condals installed extra monitors and created a single PRESCRIBE dashboard. These show operators how close they are to the AI’s control plan. Regular daily and weekly meetings help staff and supervisors share information and keep learning.

“Monitizer is now our single source of truth across the foundry,” says David. “But success also requires cultural change within the organization. It’s really a long-term, people management job to implement that.”

The result of the foundry’s hard work? When compliant with AI prescriptions, casting quality continued to improve and, by 2025, scrap rates had fallen by 54.1% on average. Condals is now extending PRESCRIBE to its Slovakian site and recently deployed DISA Trace and Guidance (TAG). TAG’s enables the collection of casting-level data which will increase data volume and accuracy to further improve AI modelling.

“We see our relationship with Monitizer as a partnership,” says David. “Monitizer’s engineers know digital but, being a sister business to DISA, Simpson and Wheelabrator, they also know the machines and the process. Working together, we can accelerate digitalization and help us keep our edge over the competition.”

Read more about Condals and Monitizer at www.monitizerdigital.com/news/condals-case-story/