Continuous vibrators of the AV range can be easily integrated into continuous manufacturing processes or clock controlled production cycles. |

Increased economic efficiency and productivity in continuous vibrators

At last year's Gifa foundry trade fair, Walther Trowal presented a new generation of its AV range of continuous vibrators for deburring and surface finishing tasks. The machine processes die castings and stampings of small and medium size. With the new multi-vibration - or Multi-Vib - technology, Walther Trowal has dramatically cut the machine's energy requirement.

By using the new Multi-Vib drive, energy consumption of the continuous vibrators is reduced by 35 percent without compromising on the machine's processing capacity and performance. Walther Trowal achieved this by improving the power input into the machine and at the same time reducing the installed power of the drive engine.

During Trowalizing (mass finishing) in the AV continuous vibrator, the work pieces are moved along a vibrating working bowl filled with chips acting as media, compound and water. The new Multi-Vib drive, featuring four to eight eccentric drive units depending on the machine size, achieves an extremely high and, at the same time, uniform power input along the complete trough length, ensuring intensive contact between the work pieces and the media.

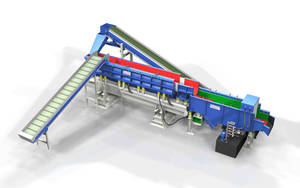

A continuous vibrator ready for shipment. |

The fact that the energy is input uniformly along the complete trough length avoids any dead zones. As all work pieces move down the same continuous process, the machine delivers reproducible results. The processing time - in other words, the intensity of the process - can be freely selected between 4 and 25 minutes by setting the frequency of the discharge vibrators accordingly.

For Christoph Cruse, Sales Director of Walther Trowal, not only the savings on energy make Trowalizing a highly efficient process: "Surface finishing can only be efficient and provide high quality, if the processes are analyzed holistically and the parameters are individually adapted to the specific processing task. Based on tests carried out in our technology lab, we select the optimal machine and the best suited media and compound together with our customers."

Downstream of the processing trough, the work pieces pass a rinsing unit and a dryer. They are discharged from the machine in a clean and dry condition - ready for packing or further processing.

The drive unit was optimized by the new Multi-Vib concept. |

In foundries, the continuous vibrators can be easily integrated into continuous or clock controlled manufacturing cycles, as loading of the work pieces in batches is generally not necessary. Bulk material is filled into the buffer unit unsorted. Large items are placed on the feeding conveyor by hand or robot.

Thanks to their modularity, the continuous vibrators can be flexibly integrated into automated production in continuous processes or clocked-controlled cycles and easily adapted to changing requirements, different types of work pieces, geometries and new manufacturing processes.

The material handling effort is low enough for a single operator to load and unload the complete system. Also the automation effort is low, as the vibrator and the peripheral devices operate continuously, requiring no additional external controls.

In addition to the mass finishing equipment itself, Walther Trowal also supplies all peripheral equipment such as intelligent loading and transportation systems, automatic lifting and tilting devices, rotary storage tables, buffer units as well as screening, shielding and noise reducing equipment. The process water is continuously recycled within a closed circuit

| Walter Trowal GmbH & Co. KG is a leading supplier for "Surface treatment" and "Enviromental protection and waste removal". For further information and contact details click here: Walter Trowal GmbH & Co. KG |