By Andrew Halonen, Mayflower Consulting LLC (Also published on LIGHT METAL AGE)

Regardless of whether a vehicle features an electric or internal combustion engine (ICE), there are many factors that affect the fuel efficiency and range in its design. Efficiency losses can come in many forms, but are generally affected by factors such as aerodynamics, rolling resistance, friction losses, and weight. Aerodynamics is perhaps the largest lever in controlling fuel efficiency, but is limited by the function of the vehicle and its design aesthetics. Rolling resistance is largely about the impact of the wheels, which have to be balanced for durability and traction. Friction losses are related to the function of the engine. Vehicle weight is the sum total of the body and systems, plus the advisable payload in terms of passengers, cargo, and towing. Weight can be optimized through a combination of design and material selection, which is the focus of

this article.

Weight and Range

In order to consider the effect of weight on efficiency and range in EVs, it is good to begin with a baseline understanding by comparing an ICE vehicle structure with an EV structure. For the purposes of this comparison, the curb weight (the weight of the vehicle without people or cargo) will be considered. In an ICE vehicle, the average sedan will typically have a weight distribution as follows:1 body structure (25%), powertrain (25%), chassis and suspension (21%), interiors (14%), closures (8%), and glazing, electrical, and fluids (7%). Combining the body and closures, the sheetmetal comprises roughly one-third of the vehicle weight. In the case of a four-door Ford Fusion, the overall curb weight would be around 3,600 lbs (1,633 kg). Meanwhile, in an EV, the weight distribution shifts. For example, for a Tesla Model S2 with a curb weight of 4,600 lbs (2,087 kg), the weight distribution would be as follows:2 battery (29%); motor, drivetrain, brakes, and suspension (23%); frame (17%); interior (14%); closures (4%); electrical (4%); and other components (9%). Automotive engineers often point out that “EVs add 1,000 lbs to the vehicle,” which has been illustrated by the comparison of the Ford Fusion to the Tesla Model S just discussed. Often the battery pack is the culprit for the increased weight. For example, the Tesla Model S battery pack weighs around 1,323 lbs (600 kg). In another comparison, the proposed Rivian EV pickup is expected to weigh an average of 800 lbs (363 kg) more than the average weight of the Detroit Big 3 pickup trucks—the Ford F-150, Chevy Silverado, and Dodge Ram. Lux Research created a model that compares EV range to vehicle mass and battery size.3 In this relationship, EV range is extended by either reducing the vehicle mass, or by increasing the battery efficiency in order to reduce its size. Certainly, there is a big cost element involved in these choices, as EVs need to become affordable to achieve mass acceptance among customers. Lux predicts that “battery pack energy densities will increase by roughly 15% over the next decade. This increased energy density can be used to either extend the range of a vehicle by keeping battery size the same or reduce cost

by shrinking the size of the battery pack.” They also predict that by 2030, the cost value of weight reduction in an EV will be around $5/kg, much the same as it is today in ICE vehicles.

Tackling Weight Reduction

When discussing the lightweighting of a vehicle, one can’t help but wonder at the various factors that go into making the multitude of decisions involved. Does the vehicle need to cut weight, and if so, where is the best value, or as Americans say, “bang for the buck,” in lightweighting

certain aspects of the vehicle?

Some systems within a vehicle cannot be or are difficult to be changed, such as the engine, battery pack, or motor. Designed by the OEMs, these systems are considered to be “black box,” or systems that have been locked in by the automakers. One can still suggest an optimized

material for these areas, but it will be a hard sell.

However, when considering the remainder of the vehicle, the decision matrix for materials selection presents many more options. Over the years, the Lightweighting World Expo has presented a vast number of lightweighting solutions for components throughout the vehicle— shifting from glass to polycarbonate windows (a 40% weight reduction); moving from steel to extruded aluminum cross car beams; switching out one type of bumper for another; and so on. Improvements in lightweighting are maturing on a regular basis.

Chassis and Suspension: One of the lesser known areas for lightweighting is under the vehicle. In the chassis, suspension, and brake systems, there are many parts to consider for lightweighting optimization. Within each system, there are a variety of options in terms of weight

and cost.

Generally speaking, the steel solution is heavier and the lowest cost. However, the aluminum industry should not fall into complacency, assuming the material will always be lighter than steel. After the Ford F-150 turned to an aluminum-bodied construction, the steel industry made considerable innovations in materials and processing. Today, automakers can purchase formable ultrahigh- strength steels with a strength of around 1,500– 2,000 MPa. For example, Mayflower Consulting predicts that the steel industry will soon be able to provide suspension arms as a one-piece stamping, further reducing weight and cost. To OEMs, this competitive landscape makes for better options to develop a profitable vehicle. However, for materials suppliers, it forces them to innovate in order to survive.

As materials producers across the board continue to innovate, it presents a challenge for OEMs in selecting between all of the available options. For suspension components, automakers have many options for producing front lower control arms, including forged aluminum, cast aluminum, and welded steel.4 There are also options for stamped steel and cast ductile iron, presenting a total of five choices for OEMs—just for a lower control arm. Forgings are common on both ICE and EV vehicles and are often used in suspension systems for steering knuckles, control arms, and links. When asked why aluminum forgings were a good choice for front-end EV suspensions, Kerry Kubatzke, sales manager for Anchor Harvey Components, commented that the EVs require long control arms with strong end fittings, and that the forging can be engineered to be a strong, stiff member that is well-suited to the needs of the design. A good example of this implementation is in the new Ford Mustang Mach- E electric vehicle, which demonstrates one of these long, forged aluminum lower control arms (Figure 1).

The use of forgings will likely grow in the EV market for several reasons. First, the vehicles are heavier. Second, EV sport packages will need higher performance (for example, in the ludicrous mode on the Tesla Model S). Finally, the center of gravity shift in an EV, which is rearward and downward, puts more load on the suspension components. Forgings address these aspects by presenting efficiency in design and packaging.

Braking Systems: In lightweighting, automakers first look to the low-hanging fruit, which is defined as bolt-on parts that are easy to swap out because they require less integration. There are a number of these kinds of components throughout the body of a vehicle. Larger weight items include the subframes and suspension arms, while smaller components include brakes and brake calipers. Brake calipers are in the category of unsprung mass (encompassing the suspension, wheels, and other components directly connected to them), which usually carries more value. When someone claims that every gram matters, the first question to ask is what materials did they choose for the brake calipers? The Ford Explorer chose cast aluminum calipers on the front, while the Chevy Blazer chose cast iron calipers. The difference between the two is the weight 2,900 g on the front axles. However, in a recent market study by Mayflower Consulting, it was found that the majority of the brake calipers on the market are still iron. This raises the question as to why automakers don’t seem to think those extra grams matter? Where else can a carmaker cut 2.9 kg, and how much effort and investment would it take? Mayflower is continuing to investigate the cost of casting and machining iron versus aluminum, so that the OEM preference for the heavier brake calipers can be better understood.

EV Material Choice Comparison

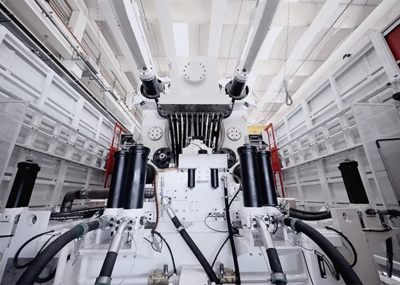

Most sedans have a unibody construction where thestructure is built into the body, rather than a body-on-frame style construction, which is popular with larger vehicles like pickup trucks. Without frame rails, the larger chassis subsystem includes the subframe, which is referred to as the engine cradle or K-frame. Materials available for subframes include aluminum extrusions, extrusions with cast aluminum corners, aluminum or magnesium castings, or steel weldments. EVs use a mix of these options. For example, the Tesla Model S has an aluminum subframe, which is considered a hybrid because it is made of extrusions joined by castings on the corners.5 Here is a comparison of subframes used on two different EV models—the 2019 Tesla Model 3 to the new 2021 Ford Mustang Mach-E (Figure 2). The Model 3 uses a welded steel subframe that weighs 24 kg (53 lbs). The upsides on the steel design are tight packaging and lower costs, but the downsides are the increased weight and lower corrosion resistance. On one hand, it is not surprising that the rear subframe uses welded steel, since

the company moved to a mostly steel body on the Model 3 (after moving away from the all-aluminum body of the Model S). On the other hand, on its Model Y, Tesla has gone with a different approach, converting the many steel stampings in the vehicle’s floor structure to a single large aluminum casting, referred to as the “mega-casting.”

Meanwhile, the Ford Mach-E features hollow cast aluminum subframes in both front and rear (with the rear frame weighing only 18 kg, or around 40 lbs). This cuts about 12 kg from the vehicle weight, resulting in an estimated 25% reduction. The hollow aluminum subframes are produced on a low pressure casting machine using a large sand core to create the hollow. Munro & Associates, a benchmarking and design firm, expressed their enthusiasm for Ford’s engineering expertise in designing the new Mache-E subrame components.

Another comparison can be made with the ID.4, Volkswagen’s new EV model. Munro & Associates did an analysis of the vehicle’s systems and noted that steel dominates the structures and suspension components. The subframes are welded steel, and the front suspension is a MacPherson strut design with a steel lower control arm and a cast aluminum knuckle. In the rear, steel is used for the subframe and lower control arm links. There are also two forged aluminum upper control arms, and a cast aluminum rear knuckle.

Taking a look at brake calipers, most in the industry are made of iron. However, on EVs, the opposite is true, with most being made of aluminum. All of the Tesla models studied by Mayflower feature aluminum calipers. Meanwhile, the Mach-E has a large aluminum caliper in the front, and a small iron caliper on the rear. It is interesting to note that the Mach-E’s rear gray iron brake disc is thin, rather than being thick and vented as on the Tesla Model 3 caliper. The use of the thin and solid design over the

thick and vented one is nearly 5 kg, though the use of an iron caliper adds some weight back in when compared to the aluminum versions. This raises the question as to why these two vehicles, both close in weight, have selected very different rear brake sizes? Perhaps Ford is right in that rear EV brakes need lesser performance Figure 1. An aluminum front lower control arm on the 2021 Ford Mustang Mach-E. Figure 2. Comparison of rear subframe systems—the 2019 Tesla Model 3 system is made of welded steel and weighs 24 kg (53 lbs), while

the 2021 Ford Mustang Mach-E system is made of a hollow aluminum casting, weighing 18 kg (40 lbs). and so it can be of a thinner design. This theory may be proved by evidence of the Volkswagen ID.4, which follows a similar methodology, using a drum brake.

The Future of Lightweighting

Intuitively, the lower the weight of the vehicle, the longer it will travel on a unit of energy. So, there is always an emphasis on efficiency, yet of course there are limits such as the available budget, the package space to fit a lightweight component, and an available supply chain to deliver reliable and competitively priced parts.

In the analysis, the Tesla 3 has a welded steel subframe much like the VW ID.4, so a host of reduced weight options such as a hollow aluminum casting or an extrusionbased design were not selected. Was this due to cost, packaging, crash performance, or vehicle dynamics? Was it because the Model 3 will be produced on many continents and steel is easier to source?

However, the Tesla 3 did select aluminum calipers on the front, delivering a weight reduction of nearly 3 kg. Is there a need for unsprung mass reduction on the front wheel-end, or is the weight reduction necessary for vehicle weight balance? In the referenced study, the majority of ICE vehicles use ductile iron brake calipers, whereas most EVs use cast aluminum. Some say the premium multiplier on weight reduction is $5/kg, which Lux Research suggests will be the metric in 2030, so perhaps the value of lightweighting is not going to change.

Ducker Research refers to suspension and brake parts as “pendulum parts,” meaning the material changes to and fro depending on the person making the decision. In the late ’90s, one Detroit OEM’s brake calipers were almost all aluminum, now they are mostly iron. Maybe the same is true in control arms, knuckles, and subframes? You can bet that there is a great debate each time the chief engineers and vehicle teams are challenged to meet the weight, cost, range, and performance goals. All we can do is keep on innovating!

References

1. AluMag, North American Lightweight Procurement

Symposium, November 2015.

2. “Tesla Model S Weight Distribution,” Teslarati, July

19, 2013, www.teslarati.com/tesla-model-s-weight.

3. By 2030, Battery Electric Vehicles Will Be Less Reliant

on Lightweighting,” Lux Research, November 12, 2020,

www.luxresearchinc.com/press-releases/by-2030-battery-

electric-vehicles-will-be-less-reliant-on-lightweighting-

according-to-lux-research.

4. Halonen, Andrew, “Automotive Suspension Components

Present Opportunity for Aluminum Forgings,” Light

Metal Age, December 2020, pp. 30-34.

5. “Subframes and Engine Cradles,” Aluminum Extruders

Council (AEC), www.aec.org/page/subframes-enginecradles#

tesla.

6. “2021 Ford Mustang Mach-E: E3 - Hoist Review | Front

Suspension,” Video, Munro & Associates, April 28, 2021,

www.youtube.com/watch?v=sq_cQWYMoC8&t=303s.

7. “2021 Volkswagen ID.4: E3 - Hoist Review, Front and

Rear Suspension,” Video, Munro & Associates, Apr 12,

2021, www.youtube.com/watch?v=HkJXkWC9G_0. n

Andrew Halonen is president of Mayflower Consulting, LLC, a lightweighting consultancy that provides strategic marketing, market research, and business development for high tech clients. Halonen works with castings, extrusions, brakes, and new material development programs.

Contact him at: www.lightweighting.co.