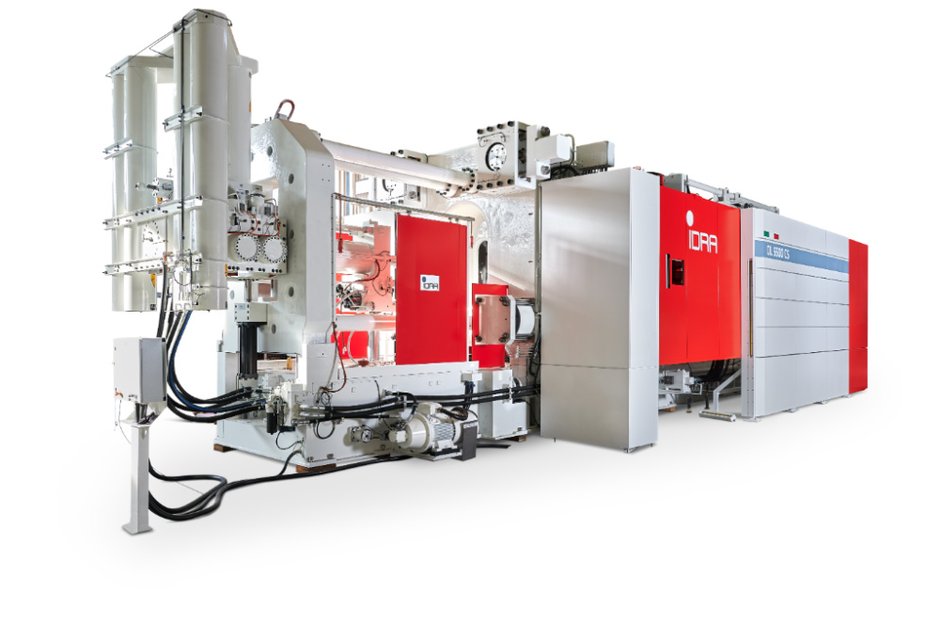

As we heard from Tesmanian and Reuters, the new Tesla plant in Germany in Brandenburg close to Berlin could be supplied with up to eight Gigapress Machines by Italy's specialist for diecasting machines, IDRA.

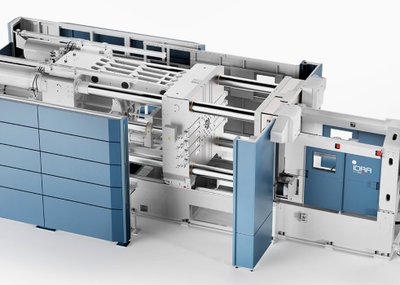

For the new Model Y, Elon Musk announced to replace 70 components glued and riveted into the car´s rear underbody with a single module alumunium casting produced on a diecasting machine.

This should be only a kind of start of the new automation, front parts and other big structure parts should follow.

Neither Tesla nor IDRA wanted to comment the current development, but Musk´s strategy seems to be clear. The reduction of several manufacturing steps replaced by few aluminium diecastings as part of modules. As we asked experts from the different point of views from diecasting, mechanical engineering, toolmaker and the automotive industry, they agree that this brave strategy is generally possible if all parameters are running in perfection and then it should be real to optimize the structure of efforts, materials and costs with a respectable calculation.