The objective of the conference is to advance the technical knowledge and showcase innovative, effective solutions for the mould temperature control technology for high pressure die casting (HPDC) process and component optimization. There were total of six presentations being delivered with the aim to share valuable insight to the industry players whom are with experiences ranging from technical & production management, product & mould designers, moulding & tooling manufacturers, QA/QC, CAD/CAE specialists and R&D personnel.

The event started with a welcome speech delivered by Mr. Jan Eilers, General Manager of MAGMA Engineering Asia-Pacific. “We are all on the road to an endemic situation and looking back on the last 2 years, Covid-19 was and still is affecting all of us, some more than others. The disruption to global supply chains, chip shortages, work-from-home, travel restrictions and uncertainties make this a challenging time for businesses and employees alike. That’s also one of the reasons why we’re organizing this event as a virtual live conference today.” said Mr. Jan Eilers.

“The terms ‘Industry 4.0’ and ‘Digitalization’ have become quite dominant in recent years and most companies have realized that the way forward to grow in our competitive landscape is to invest into technology. May it be into selecting the right mould steels and tools, additive manufacturing for prototypes and metal 3D printing or advanced spraying technologies and top notch machinery. And of course, digitalizing the metal and plastic injection moulding processes with the help of simulation.” enthused Mr. Jan Eilers in his welcome speech to kick start the presentations.

Dr. David Wang, Managing Director from voestalpine Technology Institute (Asia) had the honor to be our first presenter and illustrated how vTI enables Additive Manufacturing to emerge as the main part of the tooling solution, via innovative material solutions and processing to high-value industrial applications. During his presentation, he emphasized how the company delivers solutions to their customers by combining design and simulation in digital space with “Reality” - the manufacturing process including performance testing before the actual production.

Following next, Mr. John Belyk, Global Business Development Director from Chem-Trend, the most proven partner in the world for release agents, shared about how they partnered with their customers to help unleash product quality, effectiveness and productivity. His presentation also gave insights on how Chem-Trend creates solutions for a sustainable world with their HERATM Micro-Spray Technology.

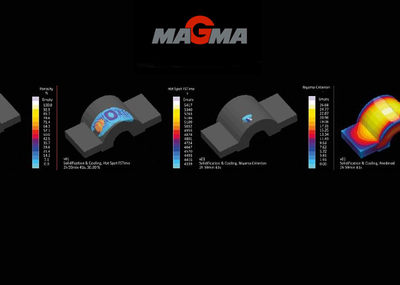

The third presenter, Ms. Luciana Stuewe, Technical Director from MAGMA Engineering Asia-Pacific, delivered on the subject: “HPDC Virtual Temperature Control Optimization”. She shared some interesting case studies on how MAGMASOFT® minimized cycle time and improved die life with conformal cooling anvil of a structural part mould and compared different mould manufacturing technologies to improve the cooling in a runner block insert.

Then Mr. Jason Ye, Technical Director from voestalpine High Performance Metals Pacific, presented how voestalpine delivered solutions to optimize die performance and elevates success economically. He also shared several insightful case studies about heat checking and a joint study about reduction in CO2 emissions with Dievar steel - which, in no doubt, evidently portrayed their position being the world’s leading supplier in delivering high quality mould and die steel.

After the fourth presentation, we had Mr. Rene Hordijk, Managing Director from Frech Asia, introducing the ways to efficient mould temperature control, including Overall Equipment Effectiveness (OEE) and die design in relation to efficient die temperature control.

Lastly, Mr. Vimalanand Devadass, Technical Manager from SIGMASOFT® Singapore, wrapped up the event by presenting on how the simulation software is specifically developed to overcome today’s challenges for mould materials and cooling system optimization for plastic moulding. He emphasized on the importance of understanding the temperature distribution in the mould and showcased the impact of productivity by achieving homogeneous temperature with the SIGMASOFT® Virtual Moulding approach.

The conference has successfully attracted sign-ups for more than 300 registrants from 18 countries although the focus of the conference was for the Asia market. If you have missed the live conference, you may scan the code to view the conference program and watch the recording.