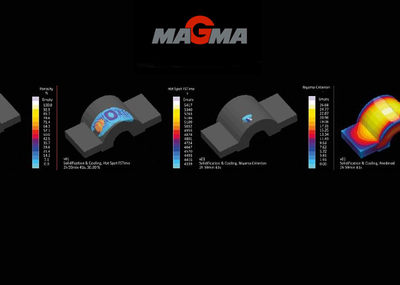

Gone are the days when foundries, die casters, plastic and rubber manufacturers were compelled to use trial-and-error methods in metal casting and injection moulding, which often lead to higher defect rates. MAGMA helps clients implement robust processes through MAGMASOFT and SIGMASOFT, its market-leading simulation software for the metal casting and injection moulding industries.

While MAGMA in Singapore began in 1996 and serves as headquarters for Asia today, the company’s roots go back to its global headquarters in Germany in 1988. From there, MAGMA’s customer-centrism, dedication to innovation and unrivalled expertise propelled its expansion. MAGMA now serves customers in more than 60 countries through 30 qualified partners, along with offices and subsidiaries in the United States, Brazil, China, South Korea, India, Türkiye and the Czech Republic.

“Metal casting has been around for thousands of years. We simulate the entire process on a computer to support a sustainable journey for the industries.” says Jan Eilers, general manager of MAGMA Engineering Asia-Pacific. “When our customers want to produce a metal or plastic part, they want to produce something of good quality as efficiently possible, and reduce material wastage and energy consumption. As an integral part of Industry 4.0, we help digitise and optimise our customers’ processes as all trial runs are done virtually, customers generate big data and waste no resources.”

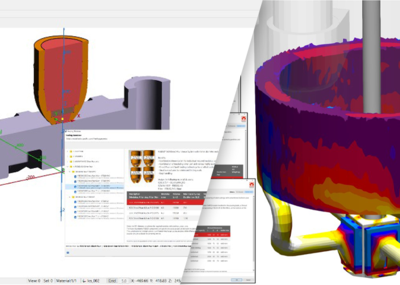

The software have aided a wide array of clientele through comprehensive 3D simulations and virtual design of experiments. The company also provides implementation, training programmes along with continuous technical support and maintenance services to licensed users.

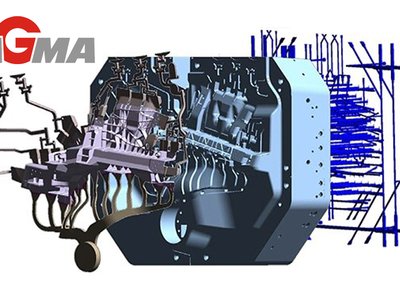

SIGMASOFT simulates the injection moulding process, considering factors such as warpage, heat flux and flow including all details of the process, to help clients create well-founded design choices.

MAGMA is continuing its path as a solution provider to shape the metal casting and injection moulding industries globally, envisioning Asean, especially Thailand and Vietnam, as a prime market for substantial growth.