Sogemi has started developing his thermal regeneration plant ,named Simplex ,at the beginning of ’90 . This system has been designed after many studies and experiences with the aim to have a plant really reliable with high performances and the lowest operative cost ,able to solve the problems of foundries of chemically bonded sand discharge .

With the thermal regeneration the foundry eliminates the cost of discharge of exhausted sand and the cost of buying new sand .

The sand inside the thermal regeneration plant has to be in granular size and free of any metallic particles .

According to the quantity resin contained in the sand , the temperature inside of the combustion chamber will be between 700 -800 °C , in order to avoid any emission of pollutants and to reach the requirement in loss of Ignition .

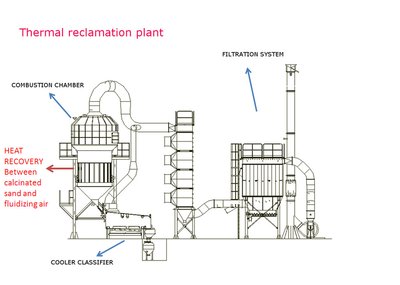

Sogemi plant is characterized by :

- Fluidized bed combustion chamber .

- Energy recovery with heat exchange between Calcinated hot sand ,coming from the combustion chamber , and fluidizing air before entering in the fluidized bed combustion chamber ,by means of a double independent circuit avoiding a direct contact between air and sand (no problem with maintenance of the air nozzles).

- Control of the weight of the sand inside of the combustion chamber by means of weighing cells .

- Complete combustion of all possible polluting substances , no need for any post-combustion .

- Proportional valve for combustion system ,to have a precise and efficient control of the elements of the combustion .

- Possibility to regenerate all chemical bonded sand types with different process : alkaline , polyurethanic , furan , shell molding , cold-box, hot box ..

ENERGY CONSUPTION The energy consumption is influenced by the quantity of resin contained in the sand , in consequence of its heating value . .

Specific consumption is hereunder reported , considering a sand with 1,5% of resin :

- Natural gas consumption (with heating value of 8.500 Kcal/Nm3) for ton of sand reclaimed : 20 Nm3/tons of treated sand , with higher quantity of resin inside the sand the consumption of Gas can reach 17-18 Nm3/ton .

- Electric power : 13 -50 Kw , depends on the size of the plant .

- Yield in weight of sand ~ 98% .

- Loss of ignition of sand after thermal treatment (LOI) : 0,01 – 0,05% , depending on customer requirements .

Sogemi produces different model thermal regeneration plant with different capacity :

SOME OF OUR LAST REFERENCE IN 2014 :

TUPY S.A in Brazil, URALVAGONZAVOD in Russia, AVIOCAST in Taiwan .