Christian Träger is new Sales Director at voxeljet Systems

Following its expansion into Asia and Latin America, voxeljet Systems, a manufacturer of progressive 3D printing systems for industrial applications, is joined by Christian Träger who will be heading up the company's international sales team. Effective immediately, the industry insider will be responsible for the global distribution of voxeljet's 3D printing systems in his capacity as Sales Director.

Christian Träger carries the German designation of Dipl.-Wirtschaftsingenieur (industrial engineer), and began to turn his focus on additive manufacturing as early as his post-secondary studies. He already started his career at voxeljet as a graduate in 2010, and worked as a project manager in the Customer Service division after completing his dissertation. Based on his extensive experience in international customer projects, he joined the printing systems sales team in 2012. Focus: Asian markets. Since August 2016, he has been responsible for the global distribution of voxeljet's 3D printing systems in his capacity as Sales Director.

“The demand for industrial 3D printing systems has grown worldwide. For this reason, we are expanding our capacities with printing systems for our subsidiary in the United States. In addition, we are also creating additional space for the manufacture of 3D printing systems and administration at the head office in Friedberg,” explains Christian Träger, the new Sales Director, with regard to the current plans of the 3D printing specialist. The eventual aim of this strategy is to expand and further develop voxeljet’s cold chemical 3D printing process, which is designed for speed.

Often worth it: Investing in your own equipment

Before customers of voxeljet Systems buy their own 3D printers, they usually take advantage of the services offered by voxeljet Services and its international service centers, which offer on-demand manufacturing services for molds and models for metal casting. As the advantages and opportunities offered by 3D printing become apparent over time, the order volume generally increases and an investment in their own equipment becomes worthwhile.

3D printer VX1000 - the top seller

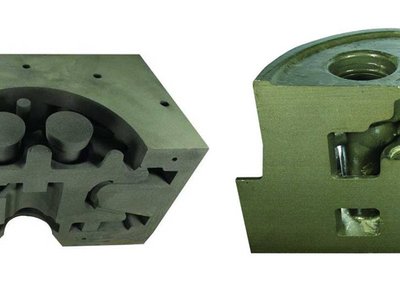

The most in-demand model is the VX1000, a universal 3D printer for industrial applications in the area of additive manufacturing. In addition to its considerable production speed, the VX1000 also impresses with its easy handling, and allows for the cost-effective production of models made from plastic, as well as sand cores for prototype manufacture. Even small series can be produced cost-effectively. In plastic processes, non-printed particle material can also be re-used. True-to-detail plastic models and precise sand cores with a high surface quality up to 1,000 mm in length and a resolution of up to 600 dpi are all possible options. The layer thickness that is applied in one pass is 150 micrometers for plastic and 300 micrometers for sand. The universal VX1000 is particularly well suited for development departments, lost-wax and sand casting.

3D printing systems for rapid prototyping and rapid manufacturing

voxeljet’s 3D printing systems are used for the tool-less and fully automated manufacture of complex components, prototypes in rapid prototyping processes and small series components in rapid manufacturing. Depending on the printing system, they can also be used for true-to-detail plastic models for lost-wax casting and precise shapes and cores for sand casting. The following applies: The more complex the geometry, the more cost-effective is 3D printing.

Other advantages: voxeljet has the world’s largest industrial 3D printer measured by continuous build volume. It can be used for the flexible production of large individual components, large numbers of small components or a combination of both. In addition, the high-performance 3D printing systems also generate enormous time savings of up to 75 percent compared to conventional tooling. The robust design ensures a long service life and is adapted for continuous operations. The industrial 3D printers are developed in Germany and manufactured with a high degree of vertical integration.

Partner

Foundry Corporate News

Topic Patternmaking, mouldmaking and tooling & Rapid Prototyping, rapid tooling

Topic Art castings

Topic Centrifugal casting

Topic Composite casting

Topic Continuous casting

Topic Full-mould casting

Topic Gravity diecasting

Topic Hand-mould casting

Topic Investment casting

Topic Low-pressure diecasting

Topic Machine mould casting

Topic Shell mould casting

Topics 3D Printing

voxeljet continues to expand its expertise in the industrial market for 3D printers

Lesedauer: min

[16]