Article also available in <link _top>

Meschede - 100 years of competence in light metals: On the occasion of its centenary, Honsel AG - founded in the Sauerland region of Germany by Fritz Honsel in 1908 - staged a jubilee day in Meschede on 15 October 2008, which began with a gala ceremony for numerous representatives of industry, the political world and universities.

In his keynote speech, the Member of the german Federal Diet, Friedrich Merz, praised the achievements of the tradition-steeped automotive supplier. Under its anniversary theme “Innovation by Tradition”, the light metals specialist had invited speakers from research and industry who, together with the top developers at Honsel, demonstrated new perspectives for lightweight construction in the automotive industry. The speakers were unanimous in stating that one of the greatest technological challenges for the automotive industry at the moment is reducing fuel consumption and thus CO2 emissions – with enhanced vehicle performance at the same time.

|

Whether casting, extruding or rolling, whether large series or flexible delivery of complex semi-finished products for specific applications, a passion for the many manufacturing methods and potential applications of aluminum and magnesium is still a tradition at Honsel today - as is the innovative spirit that drove the young Fritz Honsel and contributed to making the one-man business in the Sauerland a successful global corporation. Fritz Honsel proved to experts that aluminum and magnesium, in particular, featured exceptional dimensional consistency, strength and economics given optimum production processes. Honsel had already secured himself a competitive lead here at an early stage.

Honsel, for instance, was one of the first companies that produced aluminum components in permanent mold casting and soon became a key supplier to the still young automotive industry. The first engine and transmission components produced using the same casting method also stemmed from Honsel. Equally early, the still young company invested in die casting to be able to manufacture highly precise parts in an even more economical way. With his technical know-how and his unrelenting drive for quality, Fritz Honsel proved to be a congenial development partner for his customers. And at the threshold to the second century of the company’s history, Honsel’s engineers are still involved in the development of complex products from the very outset.

The advantages of aluminum as an especially environmentally friendly material are evident above all in the automotive area, where Honsel generates over 90 percent of its revenues. With aluminum components and systems, Honsel supports the automotive manufacturers in improving the performance, economics and safety of cars and commercial vehicles, but also in reducing vehicle weight, fuel consumption and emissions: in times of dwindling resources and growing CO2 loads, a decisive contribution to protecting the environment. In addition, Honsel is still setting trends with environmentally compatible production methods being developed continuously at all sites. Having built Germany’s first aluminum resmelting plant in Meschede in 1917, the company offers “Innovation by Tradition” here too. And not least in times of rising raw material and energy prices, optimized processes in smelting and recycling aluminum provide for better economics whilst conserving the environment at the same time.

“We placed our centenary under the motto “Innovation by Tradition” for good reasons”, said Dr. Heinz Pfannschmidt, Chief Executive Officer of Honsel AG at the gala ceremony. “It is the philosophy behind all our business dealings and relates not only to innovation in products and manufacturing processes. Especially in the globalized automotive industry, we need to reflect on our innovative power and face up to the still growing challenges”, added Pfannschmidt. On the present economic situation, he commented that the general financial crisis will drastically increase competition in the automotive industry. Suppliers, in particular, need to find creative solutions if they are to survive in the market in view of the declining production numbers. “Securing our competitiveness is top priority. Our 100 years of acquired know-how in developing innovative light metal products for our customers, and producing them in the highest possible quality in the most efficient and economical way is helping us. That is a solid basis – created over the course of an eventful company history, in which Honsel has successfully weathered many a slump – from world wars to world economic crises”, he said, commenting on the company’s prospects.

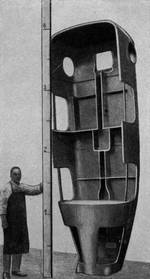

The highest topic event was the dinner surrounded by a perfect decoration of cylinder- and gearingboxes.

<link _top>Click here to visit the event picture gallery

Honsel-Symposium lectures

Klimaschutz - Herausforderung und Chance für die deutsche Automobilindustrie

Dr. Jakob Seiler, Referent Abgas und Emissionen, VDA

Leichtbau in Getriebesystemen der Zukunft

- Megatrends vom Markt

- Entwicklungstendenzen / Anforderungen

- Zusammenarbeit am Beispiel der Entwicklung eines Nutzfahrzeuggetriebes

Wolfgang Vogel, Mitglied des Vorstands, ZF Friedrichshafen AG

Powertrain 2020 - Die Zukunft fährt elektrisch

Dr. Wolfgang Bernhart, Partner, Roland Berger Strategy Consultants

Leichtmetall als Werkstoff im Antriebsstrang: Reduzierung von CO2-Emissionen bei gleichzeitiger Erhöhung der Leistungsdichte

- Einsatz von Leichtmetall am Beispiel eines 7-Gang Automatikgetriebes

- Potentiale zur Gewichtseinsparung und Leistungsdichte im Vergleich der Werkstoffe

- Schlüsselfaktoren für den Serienentwicklungsprozess

Dr. Jürgen Reusch, Leiter Entwicklung Getriebe, Leiter Konstruktion, Honsel AG

Herausforderungen an die Verbrennungsmotoren-Konstruktion

- Konzept für zukünftige Generationen von Verbrennungsmotoren

- erforderliche Material- und Fertigungs-Prozess-Entwicklungen

Dr. Bernhard Gand, Leiter Entwicklung Motoren, Honsel AG

Entwicklungstendenzen Kurbelgehäuse: Beitrag zur Gewichtsreduzierung der Motoren

- Herausforderungen an die Produktgestaltung

- Beitrag des Kurbelgehäuses zur Gewichtsreduzierung der Motoren

- Massnahmen zur Gewichtsreduzierung

Peter Stocker, Leiter Mechanik Entwicklung Grundmotor, Daimler AG

Leichtmetall in Fahrwerk und Chassis - quo vadis?

- Substitution von Stahl: Werkstoffe und Verfahren für Leichtmetallösungen

- Hybridbauweisen

- Technologietrends im Leichtmetall

Dr. Heinrich Fuchs, Leiter Werkstoff- und Prozessentwicklung, Honsel AG

Konzepte der Betriebsfestigkeit zur Auslegung von Fahrwerkbauteilen

- Definition der Betriebsfestigkeit

- Leichtbau durch Betriebsfestigkeit

- Experimentelle und numerische Simulation

- Aktives Fahrwerk

Prof. Dr.-Ing. Cetin Morris Sonsino, Fraunhofer Institut für Betriebsfestigkeit und Systemzuverlässigkeit LBF, Darmstadt

Zusammenfassung: Die zukünftige Rolle des Zulieferers in der Automobilindustrie

Dr. Helmut Becker, Leiter Institut für Wirtschaftsanalyse und Kommunikation, München

About Honsel

Honsel is one of the world's leading producers of light-metal components with primary focus on the automotive industry. The company develops and manufactures aluminium and magnesium products using the casting, extruding and rolling processes for engine, transmission, suspension and car body of passenger cars and commercial vehicles. Additionally, the company supplies products for engineering and other applications. Components and solutions from Honsel reduce vehicle weights, fuel consumption and emissions, thus contributing to environmental protection. Founded in 1908, Honsel has become a development partner and systems supplier for the worldwide automotive industry and has facilities in Germany, France, Romania, Spain, Brazil and Mexico. About 5.000 employees achieved a total turnover of almost 900 million Euros.

Foundries Catalogue: <link _top>Honsel AG

<link file:7157>

<link file:7157>