The new whitepaper presents an alternative approach: NUCLEANT 158X grain refining fluxes, now proven in the production of over 400 million aluminium wheels worldwide.

Why Foundries Are Switching

NUCLEANT fluxes address the root causes that limit Ti-B rod performance:

• Undercooling and lack of potent nuclei

• Settling and fading of rod particles

• Porosity risks from rod contamination

• Reduced efficiency in high-silicon alloys

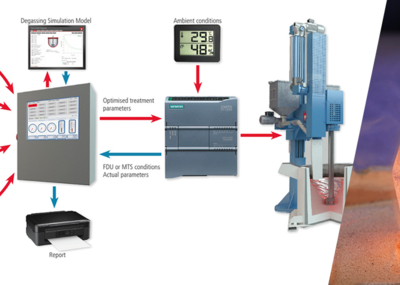

Unlike rods, NUCLEANT fluxes are added during degassing, forming fresh TiB₂ and AlB₂ nuclei evenly throughout the melt. This results in finer, more consistent grain structure and significantly reduced fading.

Proven Results from Foundry Trials

According to the whitepaper, multiple industrial trials show:

• Up to 48% lower grain refiner addition

• 45% finer grain size

• Cleaner melt with 19% less aluminium in dross

• Mechanical properties comparable to Ti-B rods

• Stable titanium levels throughout casting

This consistency is essential for modern LPDC wheel production and other safety-critical aluminium components.

A Proven Solution for Modern Aluminium Foundries

NUCLEANT 158X fluxes are suitable for all aluminium alloys—including high-silicon grades—and are already used for wheels, suspension components, and structural automotive castings worldwide.

Foundries benefit from:

• Lower operating costs

• Cleaner melts and reduced oxide formation

• Automation compatibility

• Improved process control and repeatability

Download the Full Whitepaper

This summary only touches the highlights. The complete report includes microstructure comparisons, performance data, mechanical evaluations, and practical implementation guidance.

Free Download here: www.foundry-planet.com/whitepapers/webinars/whitepapers/show/from-porosity-to-precision-how-leading-foundries-cut-grain-refiner-costs-by-up-to-50/