The global foundry industry will assemble in Düsseldorf, Germany, in June for GIFA 2023 – the leading international trade show for the foundry sector. Taking place in the halls of Messe Düsseldorf on 12-16 June, the show and associated technical forum promise the ideal chance to experience the latest trends and innovations in foundry technology and solutions.

Covering more than 900m2 in Hall 12, the Foseco stand will feature many of our recent innovations for non-ferrous foundries, including:

- Melt treatment.

- Crucibles and refractories.

- Aluminium melt shop.

- Innovative sand core binder solution for HPDC.

- Methoding and coatings for aluminium foundries

Visit our global team of experts at Stand No. 12A01/12A02 to discover how we can help solve the most pressing challenges facing the foundry industry today.

Melt treatment

In recent years, we have added a number of features and technologies to our FDU and MTS automated aluminium melt treatment technologies. These advances provide foundries the opportunity to gain new perspective on and control of their treatment process.

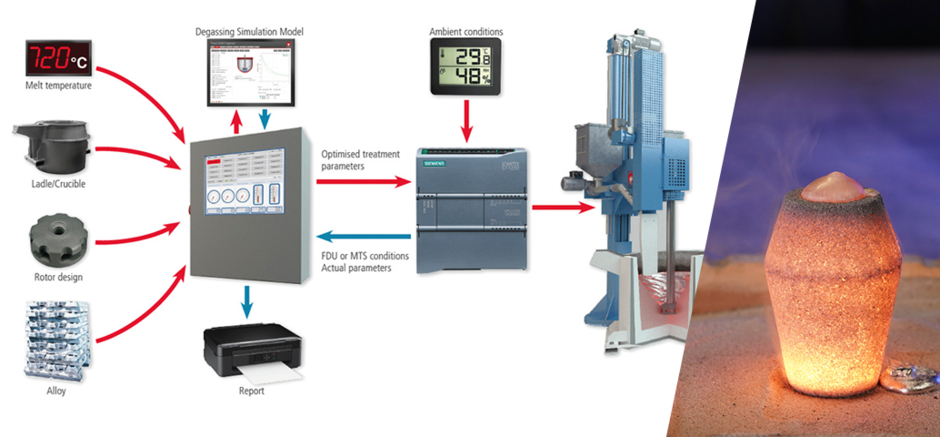

Our SMARTT degassing software offers various programs for rotary degassing; the operator must simply define a target melt quality. Based on ambient conditions, melt temperature, rotor design, and alloy composition, the software then calculates the best treatment practice to achieve that goal. Optimisation modes are also available to reduce inert gas consumption, minimise degasser wear, or provide fastest degassing and treatment speed. Treatment parameters are automatically relayed to the FDU MTS equipment, while a customised report system records all parameters.

Granulated fluxes can be added through the automated MTS and provide many advantages, such as improved melt fluidity during casting, reduced inclusions, and improved mechanical properties. Our new range of granulated fluxes includes COVERAL, SIMODAL, and NUCLEANT fluxes, which cover the principal foundry operations of cleaning, drossing, modification, and grain refinement. They have been specially formulated for use in conjunction with FDU and MTS to keep smoke and fume to a minimum.

The MTS dosing mechanism uses a gravimetric load cell to ensure highest dosing precision for best metallurgical results, as well as repeatability and traceability. Shaft and rotor design are also continuously improved to offer high efficiency degassing with long service life. The resulting dross is low in aluminium, which improves material efficiency of the process for higher yield and lower costs.

Crucibles and refractories

We continuously improve our crucible technology to provide solutions that reduce energy consumption, increase output, and improve production efficiency. Recent innovations on display at GIFA 2023 will include:

- ENERTEK ISO crucibles, which utilise a highly-insulating, proprietary Vesuvius coating to significantly reduce heat loss and decrease energy use in induction melting or continuous casting applications.

- DURATEK crucibles, designed to provide extended life, especially in highly-corrosive conditions. The latest DURATEK SUPERMELT crucibles possess superior fracture toughness, high temperature strength, and oxidation resistance to ensure long life in aggressive aluminium melting operations.

We will also highlight our refractory lining range, including ALUGARD low-cement castables, KELLUNDITE dry vibratable linings – ideally suited to coreless induction melting furnaces – and TRIAD no-cement castables, which contain a new aluminium ‘non-wetting’ additive that provides excellent resistance to corundum development across a wider temperature band.

Aluminium melt shop

The use of energy-efficient dosing furnaces in aluminium foundries is seen by many as the best available technology today. We are now able to supply a new INSURAL multi-part and highly-insulating lining, which comes ready to install, and combines energy savings with long service life and resistance to oxide build up. Installation can be achieved in less than three days with no ongoing hydrogen issues. Due to a totally dry installation process, no sintering of the lining is necessary. Energy savings can be as high as 17%.