Continuous research into the development of new metal materials as well qualification of traditionally accepted materials has helped for the technology gain wider acceptance. To understand what materials are available for 3D printing, we bring you the most comprehensive list on the metal 3D printing materials found on the web.

Metal 3D Printing Materials

- Aluminium

-

Steel

-

Cobalt Chrome

-

Titanium

-

Nickel

-

Copper

-

Refractory Metal

-

Precious Metals

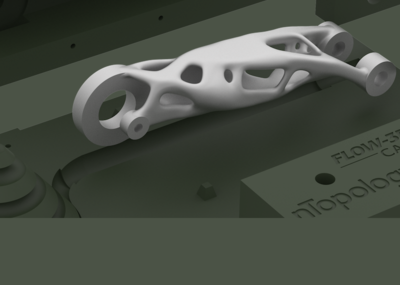

1. Aluminium Metal Additive Manufacturing Materials

Aluminium (AlSi10Mg)

Aluminium (AlSi10Mg) was among the first metal additive manufacturing materials to be qualified and optimised for 3D printing. It is well-known for its toughness and strength. It also has an excellent combination of thermal and mechanical properties, as well as a low specific weight.

Applications of Aluminium (AlSi10Mg) metal additive manufacturing material is in aerospace and automotive production parts.

Aluminium (AlSi7Mg0.6)

Aluminium AlSi7Mg0.6 offers good electrical conductivity, excellent thermal conductivity and good corrosion resistance.

Applications of Aluminium (AlSi7Mg0.6) metal additive manufacturing material is in prototyping, research, aerospace, automobiles, and heat exchangers

Aluminium (AlSi9Cu3)

AlSi9Cu3 is an aluminum-, silicon-, and copper-based alloy. AlSi9Cu3 is used in applications requiring good high temperature strength, low density, and good corrosion resistance.

Applications of Aluminium (AlSi9Cu3) metal additive manufacturing material is in prototyping, research, aerospace, automobiles, and heat exchangers.

2. Steel Metal 3D Printing Materials

Stainless Steel (316L)

Austenitic chromium-nickel alloy with high strength and wear resistance. Good elevated temperature strength, formability and weldability. Used for its excellent corrosion resistance including pitting corrosion and chloride environments.

Application of stainless steel 316L metal additive manufacturing material is in Aerospace and medical (surgical tools) production parts.

Stainless Steel (15-5 PH)

Precipitation-hardened stainless steel with excellent strength, toughness, and hardness. It has good combination of strength, fabricability, ease of heat treatment, and corrosion resistance makes it a popular material that is used in many industries.

Stainless steel 15-5 PH metal additive manufacturing material can be used to manufacture parts in various industries.

Stainless Steel (17-4 PH)

Precipitation-hardened stainless steel with excellent strength and fatigue properties. It has a good combination of strength, fabricability, ease of heat treatment, and corrosion resistance makes it a commonly used steel in many industries. 17-4 PH Stainless steel contains ferrite, while 15-5 Stainless Steel is ferrite-free.

Stainless steel 17-4 PH metal additive manufacturing material can be used to manufacture parts in various industries.

Maraging Steel (18 Mar 300 / 1.2709)

Martensitic hardening steel with good toughness, tensile strength and low warping properties. Can be easily machined, hardened, and welded. High malleability allows it to be formed easily for different applications.

Maraging Steel can be used for making injection moulding tools for series production and other mechanical parts.

CaseHardeningSteel (20MnCr5)

This case hardening steel has good hardenability and reaches good wear resistance due to its high surface hardness after heat treatment.

The material characteristics of case hardening steel makes it ideal for many applications in automotive and general engineering as well as gears and spare parts.

A2 tool steel

A2 Tool Steel is a highly versatile air-hardening tool steel often regarded as a “universal” cold-work steel. It offers a combination of good wear resistance (between O1 and D2) and toughness. It can be heat treated to increase hardness and durability.

A2 tool steel can be used in sheet metal fabrication, forming prototypes, punches, dies

D2 tool steel

D2 Tool Steel offers excellent wear resistance and is widely used in cold-work applications that require high compressive strength, sharp edges, and abrasion resistance. It can be heat treated to increase hardness and durability.

A2 tool steel can be used in sheet metal fabrication, punches and dies, wear-resistant inserts, shearing tools

4140 Steel

4140 is a low alloy steel that contains chromium, molybdenum, and manganese. It is one of the most versatile steels and is characterized by its toughness, high fatigue strength, and abrasion and impact resistance, making it a great all-purpose steel for industrial applications.

4140 Steel metal additive manufacturing material is used in applications like Jigs and fixtures, Automotive, Bolts/Nuts, Gears, Steel couplings, etc.

H13 tool steel

H13 tool steel is a chromium molybdenum hot work steel. It is characterized by its hardness and abrasion resistance, H13 tool steel has exceptional hot hardness, resistance to thermal fatigue cracking, and stability in heat treatment – making it an ideal metal for both hot work and cold work tooling applications.

H13 tool steel metal additive manufacturing material has applications in extrusion dies, injection moulds, hot forging dies, die casting cores, inserts and cavities.

3. Cobalt Chrome Metal Additive Manufacturing Materials

Cobalt Chrome (UNS R31538 / ASTM F75)

This is a very popular variant of the Cobalt Chrome metal additive manufacturing material. It is a superalloy with excellent wear and corrosion resistance. It also showcases great mechanical properties at elevated temperatures, wear resistance, corrosion resistance, and biocompatibility making it ideal for applications like surgical implants and other high-wear applications including in aerospace production parts.

CobaltChrome MP1

The MP1 also exhibits good corrosion resistance with stable mechanical properties even at elevated temperatures plus. It is nickel-free and therefore shows a fine, uniform crystal grain structure. This combination is ideal for many applications in the aerospace and medical industries.

Typical applications include prototyping biomedical implants, e.g. spinal, knee, hip bone, toe and dental implants. It can also be used for parts requiring stable mechanical properties at elevated temperatures and for parts having very small features such as thin walls, pins, etc., which require particularly high strength and/or stiffness.

CobaltChrome SP2

The EOS CobaltChrome SP2 is a cobalt-chrome- molybdenum-based superalloy powder which has been especially developed to fulfil the requirements of dental restorations which have to be veneered with dental ceramic material and has been optimized especially for processing on EOSINT M 270 systems.

Its applications include production of Porcelain-Fused to Metal (PFM) dental restorations, specifically crowns and bridges.

CobaltChrome RPD

CobaltChrome RPD is a cobalt-based dental alloy intended for production of removable partial dentures. It has an ultimate tensile strength of 1100 MPa and a yield strength of 550 MPa.

4. Titanium Metal 3D Printing Materials

Titanium (Ti6Al4V / Grade 5)

It is one of the most common titanium alloy used in metal additive manufacturing. It has excellent mechanical properties and corrosion resistance with a low specific weight. It trumps other alloys for its excellent strength-to-weight ratio, fabricability, and ability to heat treat.

Popular applications include aerospace and automotive (motorsports) production parts.

Titanium (Ti6Al4V / Grade 23)

This grade also shows excellent mechanical properties and corrosion resistance with low specific weight. This grade has improved ductility and fatigue strength to make it widely applicable for medical implants.

5. Nickel Metal Additive Manufacturing Materials

Nickel Alloy (Inconel™ 718 / UNS N07718)

This superalloy exhibits excellent yield, tensile, and creep-rupture strength at high temperatures. Its superior properties allow engineers to use the material for high strength applications in extreme environments, such as in the aerospace industry for turbine components that are regularly subjected to high temperature environments. It also has superior weldability when compared to other nickel-based superalloys.

Nickel Alloy (Inconel™ 625 / UNS N06625)

Nickel alloy, also known as InconelTM 625, is a superalloy with high strength, toughness at high temperatures, and corrosion resistance. It is suitable for high-strength applications in harsh environments. In chloride environments, it is extremely resistant to pitting, crevice corrosion, and stress-corrosion cracking. It is ideal for manufacturing parts in the aerospace industry.

Nickel Alloy (UNS N06002 / Hastelloy X)

Hastelloy X has an outstanding combination of high-temperature strength, fabricability, and oxidation resistance. In petrochemical environments, it is resistant to stress-corrosion cracking. It also has excellent forming and welding properties. As a result, it is used for high strength applications in harsh environments.

Common applications include production parts subjected to harsh thermal conditions and a high risk of oxidation (combustion chambers, burner and supports in industrial furnaces).

6. Copper Metal 3D Printing Materials

Copper has long been a sought-after metal additive manufacturing material. For a long time, it was impossible to 3D print copper, but now several companies have succeeded in developing copper variants for use in various types of metal additive manufacturing systems.

Copper fabrication is notoriously difficult, time-consuming, and costly using traditional methods. Most of the challenges are eliminated by 3D printing, which allows users to print geometrically complex copper parts with a simple workflow.

Copper is a soft, ductile metal that is most commonly used for its electrical and thermal conductivity. Because of its high conductivity, copper is an ideal material for many heat sinks and heat exchangers, power distribution components such as bus bars, manufacturing equipment such as spot welding shanks, antennae for RF communications, and other applications.

Copper

A high purity copper delivers good electrical and thermal conductivity and is suited for a wide range of applications. Copper’s material characteristics makes it ideal for heat exchangers, rocket engine parts, induction coils, electronics as well as any application requiring good conductivity like heat Sinks, welding arms, antennae, complex busbars, etc.

Copper CuCP

This commercially pure copper offers excellent thermal and electrical conductivity of up to 100% IACS which makes it ideal for inductors, electrical motors and many other applications.

CopperAlloy CuCrZr

This copper alloy has a favourable combination of electrical and thermal conductivity combined with good mechanical properties. This has had a massive impact in improving the performance of rocket chambers.

7. Refractory Metal

Tungsten W1

Tungsten W1, a pure tungsten alloy developed by EOS and tested for use on EOS metal systems, is part of the refractive material family of powders.

Parts made of EOS Tungsten W1 will be used in thin-walled X-ray guidance structures. These anti-scatter grids can be found in imaging devices used in medical (both human and veterinary) and other industries.

8. Precious Metals

Precious metals such as gold, silver, platinum, and palladium can also be 3D printed efficiently in metal additive manufacturing systems.

These metals are used in a variety of applications, including jewellery and watches, as well as dental, electronics, and other industries.

Conclusion

We saw some of the most popular and widely used metal 3D printing materials and their variants. These materials are used depending on the technology it is compatible with and the end application of the product. It is important to note that conventional materials and 3D printing materials are not entirely interchangeable. Since the process differs, the materials may show varied level of mechanical, thermal, electrical and other properties.

If you are looking at a comprehensive guide to getting started with understanding metal 3D printing, then you should check out our previous posts on Getting Started with Metal 3D Printing and a List of Metal AM technologies and also follow for more posts touching upon all the elements of metal 3D printing.

Our next post will cover a comprehensive list of metal 3D printing software available for designing.

Source: manufactur3dmag.com